My kid has the razor mx350 dirtbike and I thought it would be fun to ride with him so I picked up a beat to shit mx500. I bought some new wires and had fun this summer with him although it will need new batteries.

There is a goup on FB of these guys that modify them, some mild and some pretty crazy. Saw a guy who made a lift for his by hand and though it was cool so I figured I would do it myself and raise it 1". Came out pretty good

And you want to talk about cheap....sheesh. One guy used a fucking door hinge

I did CNC plasma some 1/8" steel and welded a nut to try it out (this was my second attempt as the first one I used 3/16".

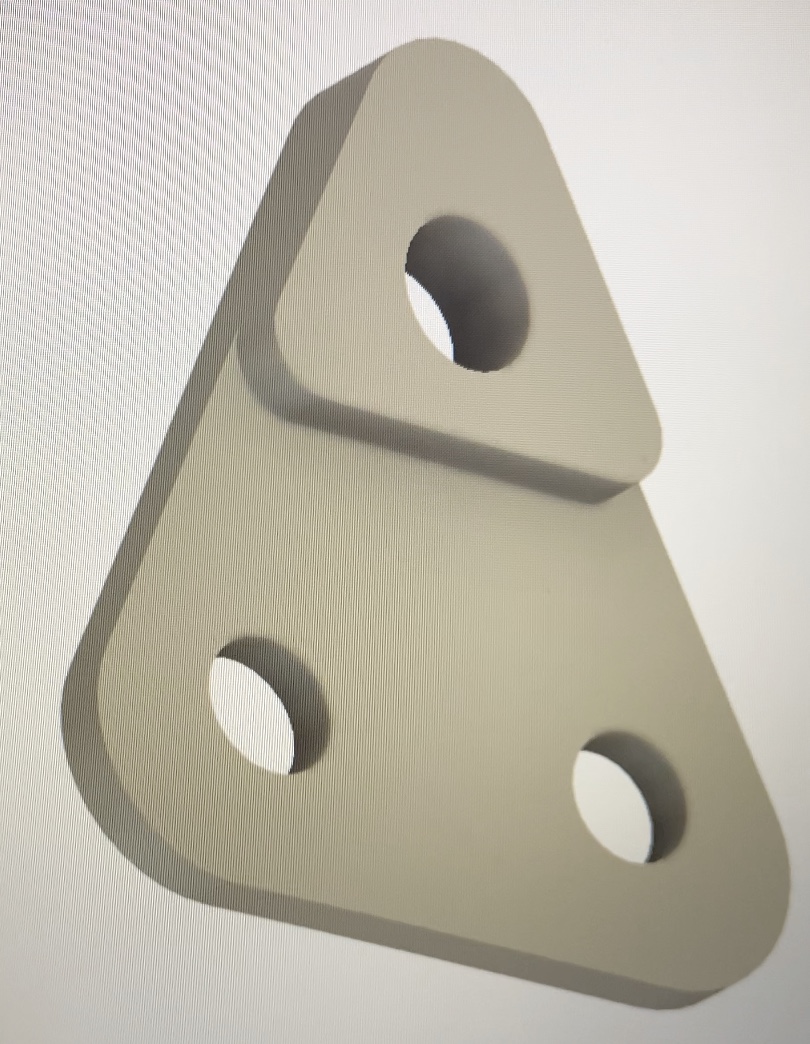

then I figured WTF i have other cool tools so mocked something up in cad and 3d printed it just because

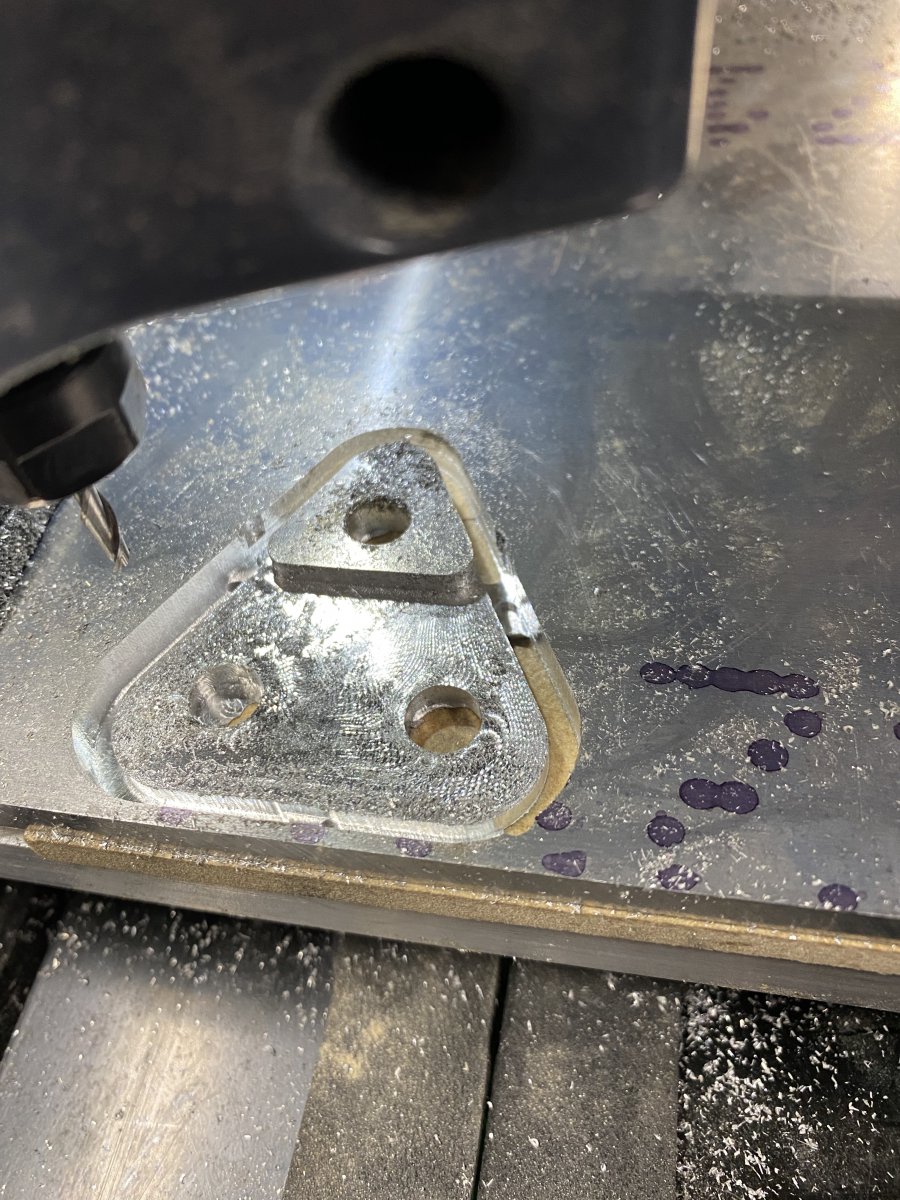

then threw on some 1/4 aluminum on the baby router and let it run. Took about 40min each piece and needed some clean up

Going to throw it on tomorrow. Was debating on swapping it for a gas motor but everyone says they run slower.....so the ego 56v batteries might be getting put on this thing. Some guys are getting theirs up to 30mph. haha

The other thing I played with is making a different size front sprocket. I used my phone gps and rode it up/down the street seeing the top speed and acceleration to find what worked best.

Probably could of machined it but its literally a 15 second cut on the plasma and a few minutes to clean up.

FYI I'm a total machining newb and teaching myself. Here are a few other things I've made recently

And 3d printed a bunch of hooks. This one is for the kid to hang his helmet on and I made a bunch more to sell that will hold the helmet and keys. Wildly strong too for being 3d printed out of PETG

Also last week went on a cleaning spree of the kitchen counter and was sick of having stuff pile up. I ordered an undercabinet mount for paper towels, a folding banana rack and then made an undercabinet mount for the alexa. Not going to lie it looks simple but shit did it take a lot of time to bend it and I quickly realized that my powder coating skills suck as I haven't done it in years so as long as nobody looks at the bottom it will pass the visual inspection from a distance.

Really hoping i may be able to pick up a simple small production run for someone soon along with piece welding but haven't had much luck yet. For now just fun crap

There is a goup on FB of these guys that modify them, some mild and some pretty crazy. Saw a guy who made a lift for his by hand and though it was cool so I figured I would do it myself and raise it 1". Came out pretty good

And you want to talk about cheap....sheesh. One guy used a fucking door hinge

I did CNC plasma some 1/8" steel and welded a nut to try it out (this was my second attempt as the first one I used 3/16".

then I figured WTF i have other cool tools so mocked something up in cad and 3d printed it just because

then threw on some 1/4 aluminum on the baby router and let it run. Took about 40min each piece and needed some clean up

Going to throw it on tomorrow. Was debating on swapping it for a gas motor but everyone says they run slower.....so the ego 56v batteries might be getting put on this thing. Some guys are getting theirs up to 30mph. haha

The other thing I played with is making a different size front sprocket. I used my phone gps and rode it up/down the street seeing the top speed and acceleration to find what worked best.

Probably could of machined it but its literally a 15 second cut on the plasma and a few minutes to clean up.

FYI I'm a total machining newb and teaching myself. Here are a few other things I've made recently

And 3d printed a bunch of hooks. This one is for the kid to hang his helmet on and I made a bunch more to sell that will hold the helmet and keys. Wildly strong too for being 3d printed out of PETG

Also last week went on a cleaning spree of the kitchen counter and was sick of having stuff pile up. I ordered an undercabinet mount for paper towels, a folding banana rack and then made an undercabinet mount for the alexa. Not going to lie it looks simple but shit did it take a lot of time to bend it and I quickly realized that my powder coating skills suck as I haven't done it in years so as long as nobody looks at the bottom it will pass the visual inspection from a distance.

Really hoping i may be able to pick up a simple small production run for someone soon along with piece welding but haven't had much luck yet. For now just fun crap