Install the TCG app

how_to_install_app_on_ios

follow_along_with_video_below_to_see_how_to_install_our_site_as_web_app

Note: this_feature_currently_requires_accessing_site_using_safari

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?I'll message ya so we're not blowin up this thread with itI have an Eastwood Ac/Dc 200 tig with the upgraded pedal. It's not a bad welder, I've just been thinking about upgrading.

My research lied once again. The pilot BEARING in the SBC is the same size as the 3800s, but the bushing that the SBC bearing rides in is obviously larger. Damn. I can put a stock 3800 bearing back in, but it won't engage the pilot shaft as deep. I don't think it will matter much. I just think the added length would give the input shaft a little more support.

I know this post is redundant, but I need to update this thread in the same manner as my build thread for the sake of documentation.

The Ford pins inside the 3800 pin trick did not work! Part of the problem was that the ford pins were too long. The other part was that the fit was a bit too tight. I can't just grind the pins shorter because there wouldn't be enough engagement in the adjustment keyway anymore. After drilling the old stuff out with stubby bits and a right angle drill, I installed brand new stock dowels. Now I'm likely back to square one. The bell at least fits nicely again. The real kicker will be if the measurements are repeatable. If they are I will be looking to bite the bullet on a set of custom made hollow and offset dowel pins. It's worth the pain of dealing with somebody else for the sole purpose of getting one of my bolt holes back. If not, I'm going to re-evaluate this entire situation. Maybe my tools suck. Maybe my bores are screwed up, or the new dowels are not exactly the same. Maybe this whole bell re-centering process is a wild goose chase. Who knows?

The Ford pins inside the 3800 pin trick did not work! Part of the problem was that the ford pins were too long. The other part was that the fit was a bit too tight. I can't just grind the pins shorter because there wouldn't be enough engagement in the adjustment keyway anymore. After drilling the old stuff out with stubby bits and a right angle drill, I installed brand new stock dowels. Now I'm likely back to square one. The bell at least fits nicely again. The real kicker will be if the measurements are repeatable. If they are I will be looking to bite the bullet on a set of custom made hollow and offset dowel pins. It's worth the pain of dealing with somebody else for the sole purpose of getting one of my bolt holes back. If not, I'm going to re-evaluate this entire situation. Maybe my tools suck. Maybe my bores are screwed up, or the new dowels are not exactly the same. Maybe this whole bell re-centering process is a wild goose chase. Who knows?

But then the bell would have the opportunity to move around and be sloppy right? I'm not below doing something like that and shoving a dab of jb in there to take up the slack though. ?I bet you could halve that just by using a drum in a Dremel along the bottom edge of the bellhousing bores letting it Center upward at least a few more.

Maybe put the bellhousing lightly on a floor jack in the upward Direction while yer snugging down

It would suck to have to redo the JB job that I'm not sure will even work every time I have to remove the bell. Hopefully that isn't as regular of an occurrence as it is now, but still!

Apparently the machinist at work took the day off, so I'll have to wait to talk to him until Monday.

Apparently the machinist at work took the day off, so I'll have to wait to talk to him until Monday.

Issue confirmed. If the machinist at work doesn't have a solution for me, I think I know what I'm going to try. Not only will I have to shave this down on both ends so that the lengths are the same, but I would have to drill all the way through. I don't think I can drill big enough to allow the bolt to pass through, but it might be enough to allow for the metal to crush a bit during installation. This will make removal and adjustment much easier.

I'll likely try this with the Ford pin just for proof of concept since I have one still in tact. If I decide to execute it, I'll probably attempt the real deal with SBC pins. It would require the 3800 pins ID to be enlarged, but the added OD of the solid SBC pin might have enough meat to safely drill it for a bolt hole. Hope of doing this all myself is restored!

I'll likely try this with the Ford pin just for proof of concept since I have one still in tact. If I decide to execute it, I'll probably attempt the real deal with SBC pins. It would require the 3800 pins ID to be enlarged, but the added OD of the solid SBC pin might have enough meat to safely drill it for a bolt hole. Hope of doing this all myself is restored!

"stop pulling a james and slap it together. 3800 other things are gonna break before thats an issue, jb weld, duck tape, zipties" -10secsomeday

The centerline is off by 12 so I need and offset of about 6.Wait a minute is your Centerline off by .010 or is your variance off by 10, or I think you said it was 12.

Centerline would be half of the dimension of the total variance

If the center lines are off by 12 then you need to adjust by 12. If the variance from one side of the board to the other on the dial indicator was 12 then your centerline's are only six thousand off from each other which is barely anything. there's probably more play in the needle bearings on the input shaft than .006

Okay, I'm saying it wrong then. 12 is what I get on the indicator, so I need to adjust by 6. While I would think the same thing, I don't want Tremec to have any reason to void my warranty. Hopefully, I never need to exercise it, but it would give me better piece of mind.If the center lines are off by 12 then you need to adjust by 12. If the variance from one side of the board to the other on the dial indicator was 12 then your centerline's are only six thousand off from each other which is barely anything. there's probably more play in the needle bearings on the input shaft than .006

???

I emailed McLeod directly in regard to the transmission. They claim that the issue is high demand. Tremec is unable to keep up with orders. That's great but it sounds like a shitty excuse to continually push my ship date back four times. Yeah, four. It's not coming until LATE July now. ? If I don't get to drive the car at all this year, I'm going to start regretting my choice to keep it a stick. I could have sold the car and converted a G-body by now.

If I don't get to drive the car at all this year, I'm going to start regretting my choice to keep it a stick. I could have sold the car and converted a G-body by now.

I emailed McLeod directly in regard to the transmission. They claim that the issue is high demand. Tremec is unable to keep up with orders. That's great but it sounds like a shitty excuse to continually push my ship date back four times. Yeah, four. It's not coming until LATE July now. ?

I guess not. I've tried figuring out what the deal is, and it seems like a lot of other people are getting theirs. I happened to buy one with funky gear ratios though.They’re still not shipping? Damn.

Just thumbed thru the tkx thread on v8buick and looks like 1 guy has a 2.87/.68 going in to his car now. He ordered from bowler transmission and they had them in stock. He mentioned the 3.27/.72 had zero eta at the time of order at the beginning of March.

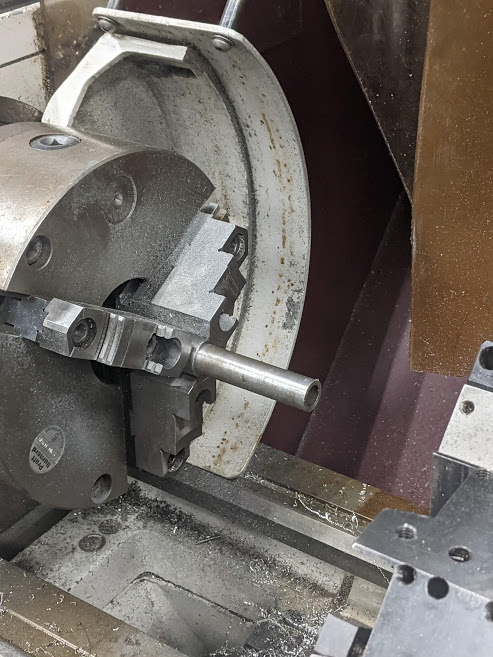

The machinist got the pins done and noted that the way he machined them required a small ring around the middle. It sounded like he was a bit nervous to chuck it back up in the lathe due to how thin they are. I can see that these are taller by a very small fraction as well, but that small of a difference probably won't matter. I think the worst case scenario will be that I need to kiss the bell and block bores with a large rill bit to clear the ring. No biggie. That would be the easiest way to tackle this anyway.

If I recall there's a fairly large countersink on the bushing bores.

Remember they can't have any metal ending up proud causing the bellhousing to not sit completely flush.

From the looks of it you should be able to blend away that ring just by using a little 2 in roloc wheel.

Remember they can't have any metal ending up proud causing the bellhousing to not sit completely flush.

From the looks of it you should be able to blend away that ring just by using a little 2 in roloc wheel.

Thread Info

-

291Replies

-

25KViews

-

Participants list