Y87 auto cars onlyany 3.42 v8 rears out there

Install the TCG app

how_to_install_app_on_ios

follow_along_with_video_below_to_see_how_to_install_our_site_as_web_app

Note: this_feature_currently_requires_accessing_site_using_safari

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?This car has 0 options. No posi. 3.23:1You at least got the posi 3.23 right?

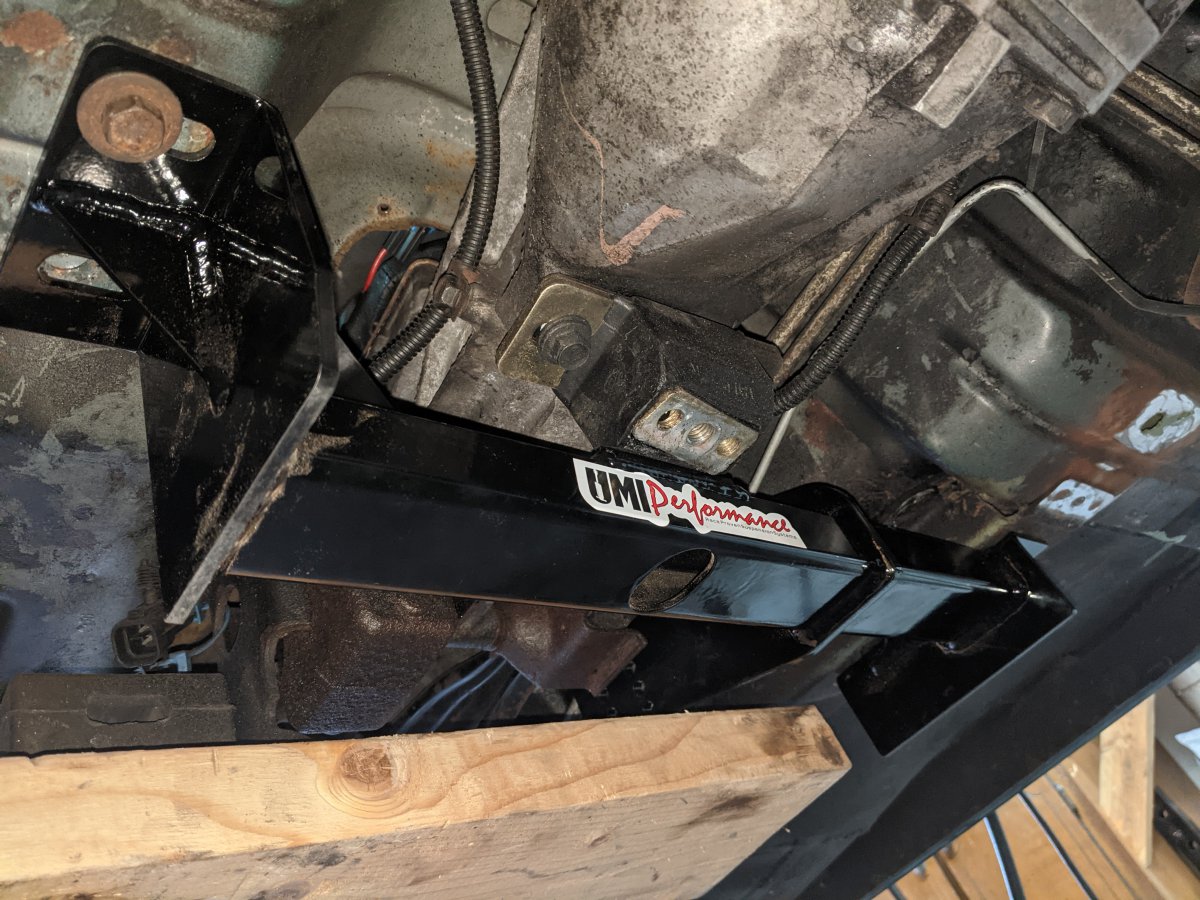

I decided to see exactly how far I was off while waiting for paint to dry. I'm kinda surprised that I was able to mount the new piece to the body with everything else still in place.

This should be an easy modification. I don't like aftermarket brand stickers on my car anyway!

A thought that crossed my mind is that a stock V6 T5 rubber mount puts the stud further back. My poly mount is why I have a bolt and my stock mounting holes are elongated. A stock mount is going to put it's stud right right where the wall of the 4L60E UMI part, so the poly T5/4L60E/700R4 mount is going to make things much easier while taking this route. Chances are that all the stock rubber mounts are shot anyway, and all the new rubber replacements are hot garbage.

I was tempted to knock this modification out really quick, but the calibration tech side of me knows that's a bad idea. The TKX mounting location is advertised as being the same as the T5, but you never know what you're going to find. I've seen stranger things! The shiney UMI piece went back to its box. It will return when I have a new transmission.

This should be an easy modification. I don't like aftermarket brand stickers on my car anyway!

A thought that crossed my mind is that a stock V6 T5 rubber mount puts the stud further back. My poly mount is why I have a bolt and my stock mounting holes are elongated. A stock mount is going to put it's stud right right where the wall of the 4L60E UMI part, so the poly T5/4L60E/700R4 mount is going to make things much easier while taking this route. Chances are that all the stock rubber mounts are shot anyway, and all the new rubber replacements are hot garbage.

I was tempted to knock this modification out really quick, but the calibration tech side of me knows that's a bad idea. The TKX mounting location is advertised as being the same as the T5, but you never know what you're going to find. I've seen stranger things! The shiney UMI piece went back to its box. It will return when I have a new transmission.

I'm starting to dig into the more minor details of the conversion and I'm running out of talent. lol

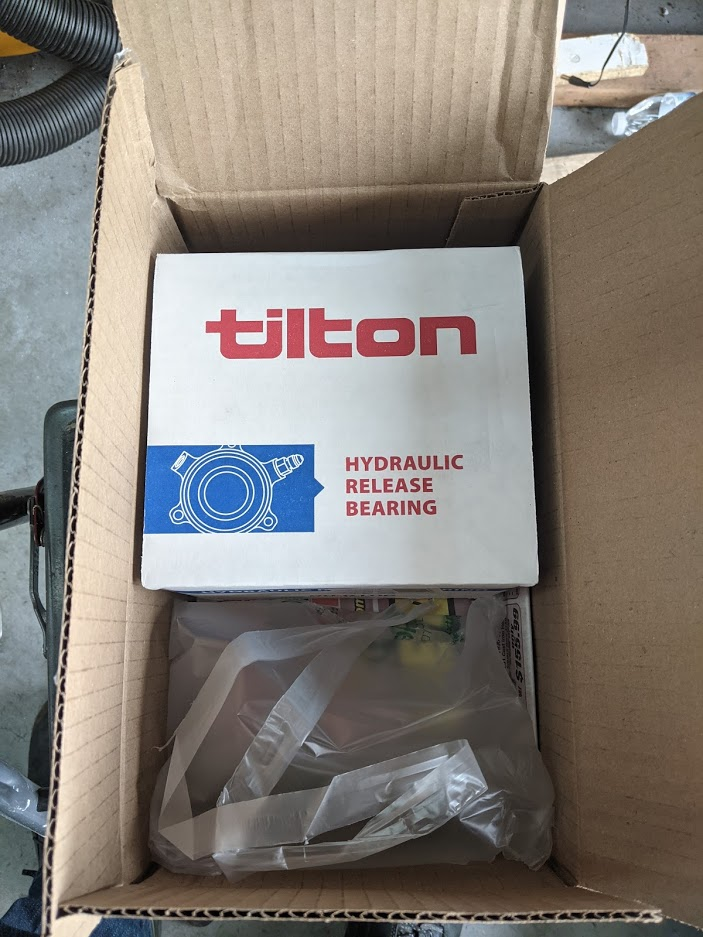

What noobs fail to remember is that there is a lot more a manual transmission conversion than bolting one to the engine. You still have to actuate the clutch. Getting my input shaft to ride smoothly in the crank bore is already addressed, but the TKX is designed around using stock old school GM fork style release bearings. To fix that for my Camaro I found this Tilton adjustable hydraulic release bearing kit. Great! I already have an adjustable master cylinder so I'm not too worried about their final listed recommendation, but I am worried about the bearing itself.

They describe it as a "high-quality flat face bearing with 1.71" - 3.03" contact diameter fits most 8.5" - 11" bent-finger and lever-type clutches" My clutch diameter is within that 8.5" - 11" window, but the contact diameter is what I'm failing to understand. The above picture shows the actual kit I would be buying and that release bearing looks nothing like the one on my car. I tried looking up details for the stock bearing on RA, but there are a lot more dimensions which I don't understand like cone diameter. (OE 2002 Camaro T5 release bearing specs) Is there somebody in here who knows better and can help me understand what I need? Maybe the beating that comes with the kit will work just fine?

Once I get past that hurdle, I'll be stuck with the challenge of making a custom hose between the master cylinder and the release bearing. I need to ditch that GM quick disconnect. Good thing I have a hydraulic hose crimper at work. I may just need to provide my own hose.

What noobs fail to remember is that there is a lot more a manual transmission conversion than bolting one to the engine. You still have to actuate the clutch. Getting my input shaft to ride smoothly in the crank bore is already addressed, but the TKX is designed around using stock old school GM fork style release bearings. To fix that for my Camaro I found this Tilton adjustable hydraulic release bearing kit. Great! I already have an adjustable master cylinder so I'm not too worried about their final listed recommendation, but I am worried about the bearing itself.

They describe it as a "high-quality flat face bearing with 1.71" - 3.03" contact diameter fits most 8.5" - 11" bent-finger and lever-type clutches" My clutch diameter is within that 8.5" - 11" window, but the contact diameter is what I'm failing to understand. The above picture shows the actual kit I would be buying and that release bearing looks nothing like the one on my car. I tried looking up details for the stock bearing on RA, but there are a lot more dimensions which I don't understand like cone diameter. (OE 2002 Camaro T5 release bearing specs) Is there somebody in here who knows better and can help me understand what I need? Maybe the beating that comes with the kit will work just fine?

Once I get past that hurdle, I'll be stuck with the challenge of making a custom hose between the master cylinder and the release bearing. I need to ditch that GM quick disconnect. Good thing I have a hydraulic hose crimper at work. I may just need to provide my own hose.

Okay, I'm going to go out on a limb and say that it's fine.

Rock Auto is my best friend when I'm trying to cross reference or find specific part details you won't find anywhere else. I saw that Tilton made a drop-in release bearing upgrade kit for C5-C7 Corvettes which incorperates the same flat faced bearing as the TKO/TKX kit, so I checked the OE part number for Corvette release bearings. What do you know? It's the same exact thing that was put in my V6 Camaro. I'm good to go.

I'm good to go.

Rock Auto is my best friend when I'm trying to cross reference or find specific part details you won't find anywhere else. I saw that Tilton made a drop-in release bearing upgrade kit for C5-C7 Corvettes which incorperates the same flat faced bearing as the TKO/TKX kit, so I checked the OE part number for Corvette release bearings. What do you know? It's the same exact thing that was put in my V6 Camaro.

I'm good to go.

I'm good to go.Yessss!Okay, I'm going to go out on a limb and say that it's fine.

Rock Auto is my best friend when I'm trying to cross reference or find specific part details you won't find anywhere else. I saw that Tilton made a drop-in release bearing upgrade kit for C5-C7 Corvettes which incorperates the same flat faced bearing as the TKO/TKX kit, so I checked the OE part number for Corvette release bearings. What do you know? It's the same exact thing that was put in my V6 Camaro.I'm good to go.

I'm so excited, but it does hurt a bit to spend nearly $500 on 8 bolts (SR20DET ARP Flywheel) and a release bearing.Yessss!

I'm hoping to dial indicate the bell housing this week which should be a real treat considering that the new bell barely even wants to fit on the existing dowels.

We both know 500 isn't much when it comes to doin somethin worthwhile and I definitely set myself back at least that over the weekend.

This is beautiful to me tho, couple years ago me and the neighbor had to adapt an nv3500(dont quote me but I'm pretty sure) to the 5.3 he put in his c/k. The biggest hangup being how the master cylinder worked with the throwout bearing we had to use. He spent a few weeks combin the pick and pull for a master cylinder that had this weird way of attaching to the line almost like a lil spring clip inside the plastic housing and no other option was gonna work right. Anyways after alot of research a case of beer and eatin steaks off the grill with dirty fingers we had that thing in and goin at 4 am.

Didn't even think about lining it up just banged it together. Dude drives the hell out of it. It's actually his daily and he's a trucker by profession so he puts on miles just to get out of the house. That's been at least two years ago and he finally says to me the other day, "so that clutch is finally gettin a lil shaky and I just keep beatin the hell out of it, we should probably pull it back out sometime" I'd just about bet we pull it apart and put it back together right it'll pry be fine [emoji23]

This is beautiful to me tho, couple years ago me and the neighbor had to adapt an nv3500(dont quote me but I'm pretty sure) to the 5.3 he put in his c/k. The biggest hangup being how the master cylinder worked with the throwout bearing we had to use. He spent a few weeks combin the pick and pull for a master cylinder that had this weird way of attaching to the line almost like a lil spring clip inside the plastic housing and no other option was gonna work right. Anyways after alot of research a case of beer and eatin steaks off the grill with dirty fingers we had that thing in and goin at 4 am.

Didn't even think about lining it up just banged it together. Dude drives the hell out of it. It's actually his daily and he's a trucker by profession so he puts on miles just to get out of the house. That's been at least two years ago and he finally says to me the other day, "so that clutch is finally gettin a lil shaky and I just keep beatin the hell out of it, we should probably pull it back out sometime" I'd just about bet we pull it apart and put it back together right it'll pry be fine [emoji23]

I think today marks the first day of actual conversion work if you don't count planning, purchasing, and investigation.

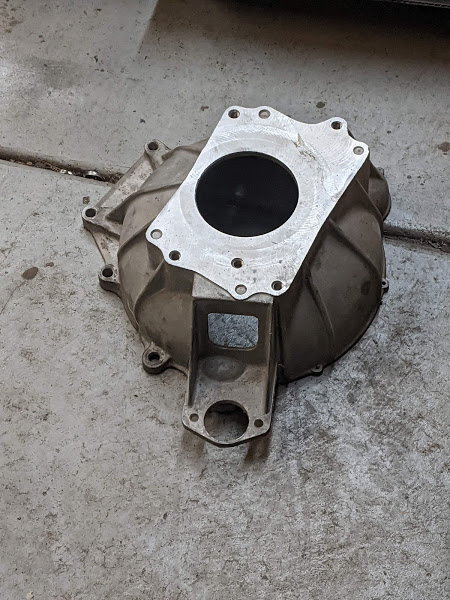

Ok, pretty but overpriced 3rd-gen F-body T5 bellhousing. It's time for surgery! Here come's the choo-choo train!

I did as much of that as I could with a sawz-all, but the funky shape doesn't allow you to get very far that way. Using abrasive cut-off wheels and flap disks for finishing is inevitable. It was a very dusty job, but this bell will fit nicely on the 3800 now. Once I drill and tap the pre-piloted holes for M12 x 1.75 it should fit nicely on the TKX as well!

If I didn't have to mess around with selling and moving my couches and diagnosing/fixing a power window issue with the 240, I probably would have had my bulkhead/inspection plate mostly done as well.

Ok, pretty but overpriced 3rd-gen F-body T5 bellhousing. It's time for surgery! Here come's the choo-choo train!

I did as much of that as I could with a sawz-all, but the funky shape doesn't allow you to get very far that way. Using abrasive cut-off wheels and flap disks for finishing is inevitable. It was a very dusty job, but this bell will fit nicely on the 3800 now. Once I drill and tap the pre-piloted holes for M12 x 1.75 it should fit nicely on the TKX as well!

If I didn't have to mess around with selling and moving my couches and diagnosing/fixing a power window issue with the 240, I probably would have had my bulkhead/inspection plate mostly done as well.

What a beaut! I'm very happy that they sent a Tilton sticker that's sized in accordance to the amount of money I spent.

And the money shot!

I'm not going to lie. This moment deserved a celebratory beverage. I was biting my nails over my research because I had read in one well written article that Muncie style T5 and actual Muncie bells had different retainer bore sizes. Whoever wrote that must be completely full of it because this retainer for Muncie aluminum bells fits perfectly in my T5 bore. As of right now, I can still call this an "easy swap" for anybody who might follow my tracks.

As of right now, I can still call this an "easy swap" for anybody who might follow my tracks.

And the money shot!

I'm not going to lie. This moment deserved a celebratory beverage. I was biting my nails over my research because I had read in one well written article that Muncie style T5 and actual Muncie bells had different retainer bore sizes. Whoever wrote that must be completely full of it because this retainer for Muncie aluminum bells fits perfectly in my T5 bore.

As of right now, I can still call this an "easy swap" for anybody who might follow my tracks.

As of right now, I can still call this an "easy swap" for anybody who might follow my tracks.I should also mention that this is the second time I've bought a Tilton component, and I think their added cost is worth every penny. The quality is apparent from the moment you open the box. I'm sure that this slave is going to work just as amazingly as my master cylinder.

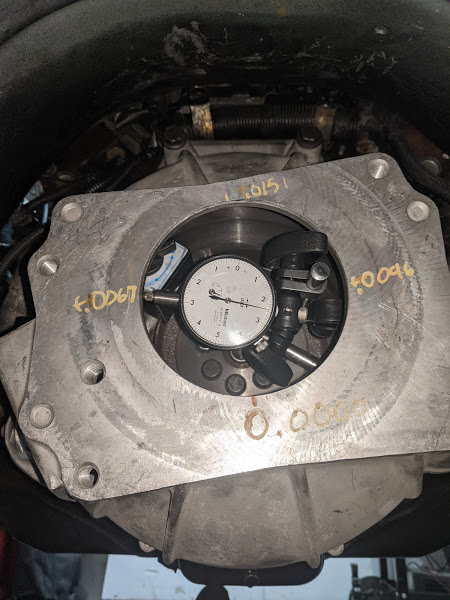

This was a massive pain for me to set up, but you really don't need a dial indicator that's calibrated to 0.0001" with a Pittsburgh base either. ? I'm going to check my work in the morning because I've found several mistakes already. I'm tired, and the math part of my brain is not working like it should.

Tremec posts a tolerance for bell run out at 0.005" which seems really tight now that I've done this. When you subtract the measurements you take on each axis, you get the run out. If I did this correctly, I happen to be in spec horizontally (0.0029") and out of spec by vertically (.0151"). What is blowing my mind is that I have a stock block and bottom end, no adapters, and an OE bell that's designed to mount a transmission of the same brand. Yet, I'm out of tolerance. I guess things change when you start getting into performance oriented stuff. Based on this information, I will need to split the vertical difference by getting 0.007" offset dowels and point them almost straight down but maybe just a hair to the left.

Tremec posts a tolerance for bell run out at 0.005" which seems really tight now that I've done this. When you subtract the measurements you take on each axis, you get the run out. If I did this correctly, I happen to be in spec horizontally (0.0029") and out of spec by vertically (.0151"). What is blowing my mind is that I have a stock block and bottom end, no adapters, and an OE bell that's designed to mount a transmission of the same brand. Yet, I'm out of tolerance. I guess things change when you start getting into performance oriented stuff. Based on this information, I will need to split the vertical difference by getting 0.007" offset dowels and point them almost straight down but maybe just a hair to the left.

It's so nice. I can't wait to install it!That tilton piece looks awesome!

This is my most ridiculous spending weekend ever. I'm getting married in November, I bought a new sectional couch last night, and I just bought a TKX today! ???

So much for my summer plans.  This email is in regards to the transmission.

This email is in regards to the transmission.

I might do a little blurb on how my offset dowel pin installation goes, but this thread is once again going to have to rest a while.

I might do a little blurb on how my offset dowel pin installation goes, but this thread is once again going to have to rest a while.

Smash another t5 in the meantime? Adapter and a th350? Hate to see it sit with all they work you've done latelySo much for my summer plans.This email is in regards to the transmission.

View attachment 83829

I might do a little blurb on how my offset dowel pin installation goes, but this thread is once again going to have to rest a while.

Nah. That's not worth my time or money. The fleet still needs enough stuff to keep me busy anyway. I still have to redrill the crank, change the oil pan, and do a little bit of rewiring. My HP Pro link needs a new ground, and the LED indicator for my line lock needs to be replaced. I can still do all that while I wait. Then the GN and 240 need some love too. I can stay busy, it just won't involve getting a transmission in the car.Smash another t5 in the meantime? Adapter and a th350? Hate to see it sit with all they work you've done lately

I don't think anybody in the 3800 community would have a reason to remove transmission dowel pins unless they were doing a fancy conversion like this so I'll post my results in here.

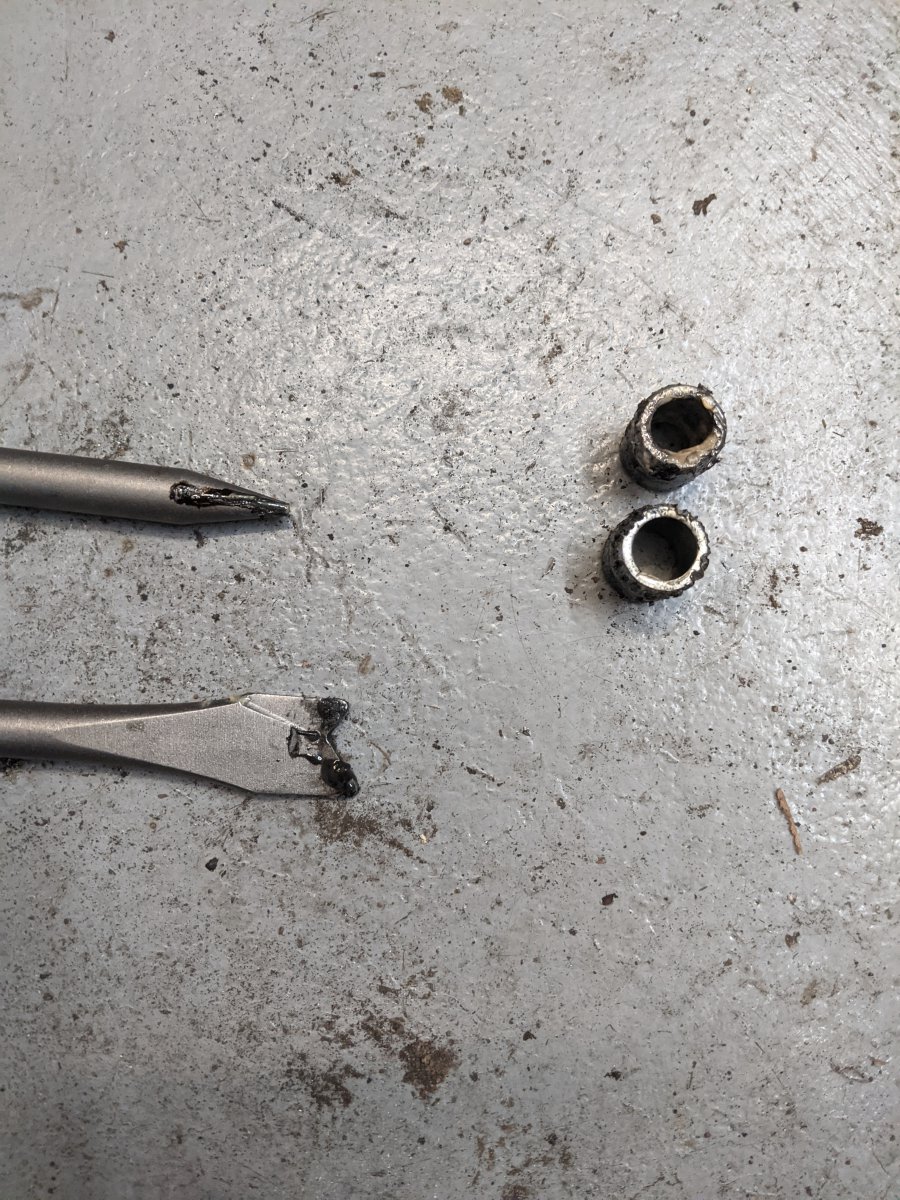

Good luck to you. I was able to make the lower one spin with PB blaster and vise grips, but there was no way to pry or hammer the suckers out without just losing grip and marring the crap out out of the dowel. Then I remembered that I got an air hammer for Christmas!

It might be hard to tell, but that bare metal dot in the middle is really deep. I punched a hole with the pointy attachment. Then I pried outward with the fork attachment wedged in the dot. I wish I thought of it an hour ago. Lol

This prompted me to finally notice another piece of the conversion that I'm not happy about. The original bell has five bolts directly to the block and two steel brackets that hold it together sideways with five bolts each. Not only am I losing both brackets, but I'm also losing one bolt. I don't know how to feel about that. Part of me says it's fine because the trans is only held to the bell by four bolts. Part of me also says there could be a lot more leverage on the bell and I'm significantly dropping the amount of clamping force. What do you all think? Find a way to incorporate the brackets? Try to drill a hole into my offset dowel so that I can use the fifth bolt? I guess I'll have to think about it. No bell centering tonight.

Good luck to you. I was able to make the lower one spin with PB blaster and vise grips, but there was no way to pry or hammer the suckers out without just losing grip and marring the crap out out of the dowel. Then I remembered that I got an air hammer for Christmas!

It might be hard to tell, but that bare metal dot in the middle is really deep. I punched a hole with the pointy attachment. Then I pried outward with the fork attachment wedged in the dot. I wish I thought of it an hour ago. Lol

This prompted me to finally notice another piece of the conversion that I'm not happy about. The original bell has five bolts directly to the block and two steel brackets that hold it together sideways with five bolts each. Not only am I losing both brackets, but I'm also losing one bolt. I don't know how to feel about that. Part of me says it's fine because the trans is only held to the bell by four bolts. Part of me also says there could be a lot more leverage on the bell and I'm significantly dropping the amount of clamping force. What do you all think? Find a way to incorporate the brackets? Try to drill a hole into my offset dowel so that I can use the fifth bolt? I guess I'll have to think about it. No bell centering tonight.

most earler cars just had a flattened end round steel bar going from somehwere on the engine block/mounts back to the lower bellhousing bolts where the converter cover was the later aluminum casting and was also a part of the drivetrain structure is also an option for making your own bracing.

id think just two pieces of 1.25" angle iron would take you 2 hours to turn into bracing matching that of oem v8 trucks.

honeslty though we broke the bell off a th400 with a nitrous 406sbc....so bell flex is a thing....might be that a couple pounds of ferrous prevention is worth more than fixing hundreds of lbs of broken stuffs

id think just two pieces of 1.25" angle iron would take you 2 hours to turn into bracing matching that of oem v8 trucks.

honeslty though we broke the bell off a th400 with a nitrous 406sbc....so bell flex is a thing....might be that a couple pounds of ferrous prevention is worth more than fixing hundreds of lbs of broken stuffs

Thread Info

-

291Replies

-

25KViews

-

Participants list