General Information

So this car has a ridiculous amount of work already put into it. Overtime I'll try to highlight some of the big points with the transmission swap and some of the other really cool details, but for now I'm going to briefly explain what the car looks like when I bought it and what's going on right now with the build.

I bought the car earlier this summer in very poor condition. All the high $$$ parts were already on the car, I've put less than $500 into it as of now. Bought the car for a great price, even if I had known everything wrong with it I still would have paid that much in a heartbeat.

The 4T80e conversion was incomplete (car wouldn't shift into 3rd gear), everything was leaking except the rear suspension air bags, lots of misfires, horrible squealing from the engine due to improper belt routing, and other things I'm probably not thinking of.

Here's what the car came with:

Engine:

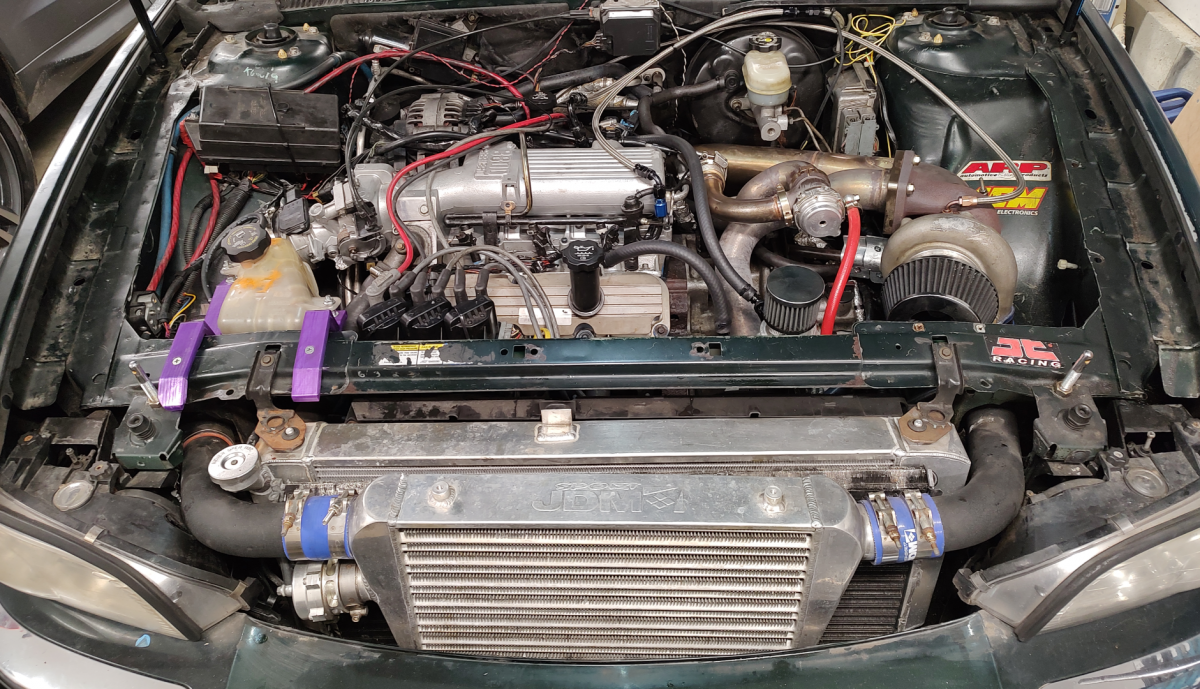

-VS Cam with new GM timing chain

-Cobb Racing one-off turbo kit

-Camaro intake for beautiful routing of the charge pipe through the air/air intercooler

-(Unsure of what turbo is on it)

-No coolant overflow

-Stock Camaro TB and MAF (MAF was getting maxed out with the springs that came in the wastegate and blowoff)

-LS3 MAF installed but not wired up or tuned

Transmission:

-Stock rebuild 4T80e from a 2000

-3.11 gears

-700+ ft-lb rated LSD

-GM axles

-Cheap transmission cooler mounted in front of the driver's side wheel (effectiveness unknown)

Suspension:

-Stock parts, maybe some stock spec aftermarket stuff

-Broken away bar links in front (makes for an extra "exciting" ride when attempting to tame 400+ HP)

-Worn out 225 mm tires

Exterior:

-Rust

-Body panels in two different shades of green

-Rust

-Front end body panels are not from an Ultra (the car is an Ultra)

-Rust

Interior:

-Bone stock with a boost gauge and wideband.

-Lots of broken interior panels

-Heat and heated seats work

Fast forward to a week ago...

My friend Daniel has had possession of the car ever since we got it. He's been dailying while stress testing and taking care of little details, repairs, tuning tweaks, and some diagnostics. It's a win win for us because he doesn't need to spend money for his own car, he really enjoys the project, and I didn't have storage space or time for another project lol...

Anyways, even though we knew the mass airflow sensor was getting maxed out, we didn't really worry about it because we weren't getting any knock. During an extended 20 plus PSI pull he blew out one of the head gaskets. I'm sure the AFR was quite lean and I'm thankful we didn't lose a piston. We will be keeping a close eye on the afrs until we rework the mass air flow sensor system.

Before we can rework the mass air flow sensor, we need to finish getting the car running good. The afrs are all over the place at idle because the oxygen sensor hasn't really been working and the used one I had laying around that we tried to put in when doing the head gaskets also isn't working. While doing the head gaskets we found that the spark plug gaps were very inconsistent from 24 thou all the way up to close to 40. After finishing the head gaskets and regapping the plugs, the misfires are gone at idle and full throttle.

Next steps will be to convert the ignition system to LS coils and try another oxygen sensor. As soon as the AFRs are good and the misfires are completely gone at the same time, we will be putting a mini AFC on the stock Camaro mass air flow sensor currently being used.

I bought the car earlier this summer in very poor condition. All the high $$$ parts were already on the car, I've put less than $500 into it as of now. Bought the car for a great price, even if I had known everything wrong with it I still would have paid that much in a heartbeat.

The 4T80e conversion was incomplete (car wouldn't shift into 3rd gear), everything was leaking except the rear suspension air bags, lots of misfires, horrible squealing from the engine due to improper belt routing, and other things I'm probably not thinking of.

Here's what the car came with:

Engine:

-VS Cam with new GM timing chain

-Cobb Racing one-off turbo kit

-Camaro intake for beautiful routing of the charge pipe through the air/air intercooler

-(Unsure of what turbo is on it)

-No coolant overflow

-Stock Camaro TB and MAF (MAF was getting maxed out with the springs that came in the wastegate and blowoff)

-LS3 MAF installed but not wired up or tuned

Transmission:

-Stock rebuild 4T80e from a 2000

-3.11 gears

-700+ ft-lb rated LSD

-GM axles

-Cheap transmission cooler mounted in front of the driver's side wheel (effectiveness unknown)

Suspension:

-Stock parts, maybe some stock spec aftermarket stuff

-Broken away bar links in front (makes for an extra "exciting" ride when attempting to tame 400+ HP)

-Worn out 225 mm tires

Exterior:

-Rust

-Body panels in two different shades of green

-Rust

-Front end body panels are not from an Ultra (the car is an Ultra)

-Rust

Interior:

-Bone stock with a boost gauge and wideband.

-Lots of broken interior panels

-Heat and heated seats work

Fast forward to a week ago...

My friend Daniel has had possession of the car ever since we got it. He's been dailying while stress testing and taking care of little details, repairs, tuning tweaks, and some diagnostics. It's a win win for us because he doesn't need to spend money for his own car, he really enjoys the project, and I didn't have storage space or time for another project lol...

Anyways, even though we knew the mass airflow sensor was getting maxed out, we didn't really worry about it because we weren't getting any knock. During an extended 20 plus PSI pull he blew out one of the head gaskets. I'm sure the AFR was quite lean and I'm thankful we didn't lose a piston. We will be keeping a close eye on the afrs until we rework the mass air flow sensor system.

Before we can rework the mass air flow sensor, we need to finish getting the car running good. The afrs are all over the place at idle because the oxygen sensor hasn't really been working and the used one I had laying around that we tried to put in when doing the head gaskets also isn't working. While doing the head gaskets we found that the spark plug gaps were very inconsistent from 24 thou all the way up to close to 40. After finishing the head gaskets and regapping the plugs, the misfires are gone at idle and full throttle.

Next steps will be to convert the ignition system to LS coils and try another oxygen sensor. As soon as the AFRs are good and the misfires are completely gone at the same time, we will be putting a mini AFC on the stock Camaro mass air flow sensor currently being used.