Hi All,

I was refered to this site by Jeff (10th03COBRA). He said that some here may be interested in my current project. With that said...

I am working on a "slightly" modified 03 Cobra that I call the SN65.

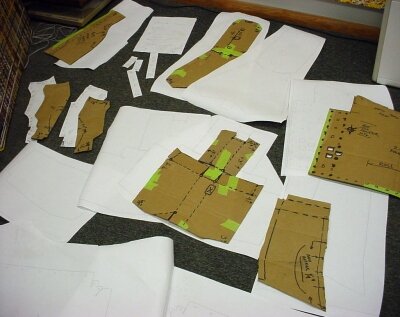

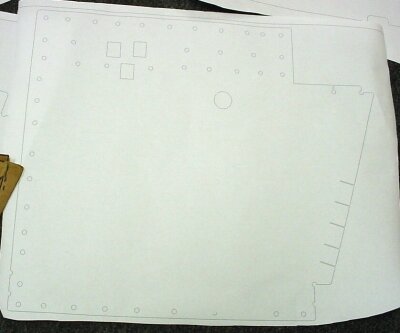

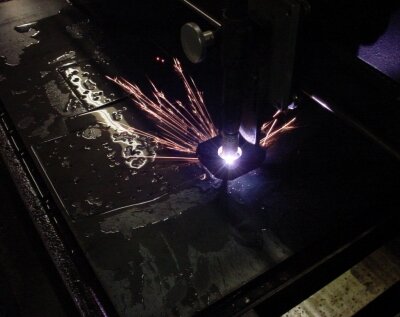

I am well beyond the stage shown in the attached photo, but I thought you would get a kick out of this shot.

I will be looking to your help in the selection of components before I actually start bolting things back together again. Right now I am detailing all the 1000 of components that are going into this project.

Wish me luck

I was refered to this site by Jeff (10th03COBRA). He said that some here may be interested in my current project. With that said...

I am working on a "slightly" modified 03 Cobra that I call the SN65.

I am well beyond the stage shown in the attached photo, but I thought you would get a kick out of this shot.

I will be looking to your help in the selection of components before I actually start bolting things back together again. Right now I am detailing all the 1000 of components that are going into this project.

Wish me luck