Install the TCG app

how_to_install_app_on_ios

follow_along_with_video_below_to_see_how_to_install_our_site_as_web_app

Note: this_feature_currently_requires_accessing_site_using_safari

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?Loving these T/A builds.

If your looking for a good price on an AEM TRU-boost they are on sale through the 20th. Shoot us an email for more info

[email protected]

If your looking for a good price on an AEM TRU-boost they are on sale through the 20th. Shoot us an email for more info

[email protected]

Here is a quick explanation. lol

The wastegate has a spring that sets base pressure on the turbo. It open and closes based on how much back pressure is pre turbo. The spring opens when the back pressure gets to a certain force. Most turbo systems have a pressure ratio of at least 1:1 on intake manifold versus pre turbine. So 12psi in the intake = 12psi of back pressure pre turbine. Most systems are higher than that. When this ratio gets worse as boost goes up. A 1:2 would be 12# intake vs. 24# pre turbine. And 1:3 would mean 12# intake vs. 36# pre turbine. As this pressure pre turbine increases the spring in the waste gate has trouble holding the valve in the waste gate shut. Now most boost controllers will add intake pressure to the diaphragm on top of the waste gate valve. To help hold the valve closed longer. The problem is as the pressure ratio gets worse the back pressure pre turbine is more than you can add on top of the valve with the intake manifold source. So no matter what you can not over come the larger back pressure with intake manifold pressure.

So lets say you want to make 25# of boost in the manifold. And have an average back pressure ratio of 1:2. That means you have 50# of back pressure pre turbine. And lets say your waste gate spring is good for 10#. SO you take 10# for the waste gate and 25# for the intake source you are at 35#. With that difference in force the valve can not stay closed. The valve opens bleeding off exhaust energy and therefore less boost.

Now the co2 tank can run upwards of 60# of pressure. So you can put 60# of force on top of the diaphragm no matter what. So you can run a 2# spring in the waste gate and let the co2 pressure and boost controller control the waste gate valve. So you can run boost as low as you want. Or let the co2 get to the top of the valve and hold it closed. Or any where in between.

I use co2 and have WAY more control over my set up now. Really is nice. And you don't use much co2 so even a 1 or 2.5" bottle will last a long time.

Hopefully that makes sense. I am in a hurry to get out of here and didn't proof read it. HAHA

The wastegate has a spring that sets base pressure on the turbo. It open and closes based on how much back pressure is pre turbo. The spring opens when the back pressure gets to a certain force. Most turbo systems have a pressure ratio of at least 1:1 on intake manifold versus pre turbine. So 12psi in the intake = 12psi of back pressure pre turbine. Most systems are higher than that. When this ratio gets worse as boost goes up. A 1:2 would be 12# intake vs. 24# pre turbine. And 1:3 would mean 12# intake vs. 36# pre turbine. As this pressure pre turbine increases the spring in the waste gate has trouble holding the valve in the waste gate shut. Now most boost controllers will add intake pressure to the diaphragm on top of the waste gate valve. To help hold the valve closed longer. The problem is as the pressure ratio gets worse the back pressure pre turbine is more than you can add on top of the valve with the intake manifold source. So no matter what you can not over come the larger back pressure with intake manifold pressure.

So lets say you want to make 25# of boost in the manifold. And have an average back pressure ratio of 1:2. That means you have 50# of back pressure pre turbine. And lets say your waste gate spring is good for 10#. SO you take 10# for the waste gate and 25# for the intake source you are at 35#. With that difference in force the valve can not stay closed. The valve opens bleeding off exhaust energy and therefore less boost.

Now the co2 tank can run upwards of 60# of pressure. So you can put 60# of force on top of the diaphragm no matter what. So you can run a 2# spring in the waste gate and let the co2 pressure and boost controller control the waste gate valve. So you can run boost as low as you want. Or let the co2 get to the top of the valve and hold it closed. Or any where in between.

I use co2 and have WAY more control over my set up now. Really is nice. And you don't use much co2 so even a 1 or 2.5" bottle will last a long time.

Hopefully that makes sense. I am in a hurry to get out of here and didn't proof read it. HAHA

Back to the boost controller issue. I'm thinking that to keep things simple for this go round I'll probably get one of those tru-boost gauges since I can return the boost/vac gauge I have and it almost becomes a wash. I just want to keep it simple so I can get this thing going then I'll start to look at the more feature rich controllers out there.

Pressure/ratio, what is your name? I hate having to keep putting in "Hey pressure ratio, blah blah blah". EDIT: Oh, I'm dumb, your name is in your sig.

Anyway, Pratt/Dan, I was going to bring up my wastegate. Currently it's set for .7 bar which I think is about 10psi. Now if I buy a set of springs to bring it up, what level should I bring it up to if I intend to have max 17-18psi in the intake. Also to add to that confusion if I get a boost controller like a simple AEM tru boost if i set two boost settings(10 and 18psi) what type of spring setup would be ideal? Would I want a set to be right at 18psi or a little over and hope that the controller backs it down? Sorry for the non technical terminology.

Pressure/ratio, what is your name? I hate having to keep putting in "Hey pressure ratio, blah blah blah". EDIT: Oh, I'm dumb, your name is in your sig.

Anyway, Pratt/Dan, I was going to bring up my wastegate. Currently it's set for .7 bar which I think is about 10psi. Now if I buy a set of springs to bring it up, what level should I bring it up to if I intend to have max 17-18psi in the intake. Also to add to that confusion if I get a boost controller like a simple AEM tru boost if i set two boost settings(10 and 18psi) what type of spring setup would be ideal? Would I want a set to be right at 18psi or a little over and hope that the controller backs it down? Sorry for the non technical terminology.

With a boost controller you usually can double what the spring in the waste gate will produce. So if it makes 10psi with just the spring it could make 20#. But it isn't exact on every combo. Again, the back pressure pre turbine will effect this. As will the size of the face on the valve. If a small and larger valve both have the same spring the larger valve has more surface area to have pressure act against. So that can effect what the spring will hold. There are formulas you can do to figure most of this out. But most people will just try 2 or 3 springs and see what they do with and with out the boost controller. But the more boost you want to run the harder it will be to rely on the boost controller to increase it when using a light spring and intake manifold pressure on top of the diaphragm. Example: 10psi of manifold pressure from just the wastegate and having the boost controller add pressure to make another 14psi should not be a problem. But asking the controller to add pressure to make another 20psi will be hard. Asking the boost controller to make another 25psi on top of the base 10psi is not going to happen with out a pressurized source like a co2 bottle.

I don't see you wanting to run 20psi or more right away. Run the .7 bar and the controller. You should be fine for a while. Once you can't add any more boost with the controller change to a heavier spring and see what happens.

I don't see you wanting to run 20psi or more right away. Run the .7 bar and the controller. You should be fine for a while. Once you can't add any more boost with the controller change to a heavier spring and see what happens.

Back to the boost controller issue. I'm thinking that to keep things simple for this go round I'll probably get one of those tru-boost gauges since I can return the boost/vac gauge I have and it almost becomes a wash. I just want to keep it simple so I can get this thing going then I'll start to look at the more feature rich controllers out there.

Pressure/ratio, what is your name? I hate having to keep putting in "Hey pressure ratio, blah blah blah". EDIT: Oh, I'm dumb, your name is in your sig.

Anyway, Pratt/Dan, I was going to bring up my wastegate. Currently it's set for .7 bar which I think is about 10psi. Now if I buy a set of springs to bring it up, what level should I bring it up to if I intend to have max 17-18psi in the intake. Also to add to that confusion if I get a boost controller like a simple AEM tru boost if i set two boost settings(10 and 18psi) what type of spring setup would be ideal? Would I want a set to be right at 18psi or a little over and hope that the controller backs it down? Sorry for the non technical terminology.

I run a 7# spring in my Tial 44mm wastegate. With my tru-boost I've seen 18psi before, and without issue. For me, I wanted to run a smaller spring so I could run with the controller off and keep the power down so my wife could drive the car without worrying about it being too difficult to drive if she did indeed decide to mash it.

Good luck, Will! I can remember the first time running 17psi on the street on 28x10x15 slicks like it was yesterday... blowing the tires off at 120mph with a passenger in the car. You're in for quite a ride man. So keep working... it'll soon pay off.

^I'll make sure to be careful too. Don't want an "oh shit" moment on 17#'s so i'll work my way up to that

The Tial 44mm i got is set at 10psi and idealy what I wanted with the a boost controller is 10psi for normal driving and 17-18 max for tracking or other scanario's warrenting that much boost. So I should be ok with that spring and and aem boost controller. Is there anyway on selecting incremental boost from 10psi? Dan I think you were calling it scramble boost or something.

BTW, block is all stripped down and ready for speed inc in the morning.

The Tial 44mm i got is set at 10psi and idealy what I wanted with the a boost controller is 10psi for normal driving and 17-18 max for tracking or other scanario's warrenting that much boost. So I should be ok with that spring and and aem boost controller. Is there anyway on selecting incremental boost from 10psi? Dan I think you were calling it scramble boost or something.

BTW, block is all stripped down and ready for speed inc in the morning.

Scamble boost is for adding 3psi at a push of a button. You can hit the button 3x and have 9 additional psi added to your spring+controller psi. So if your spring and controller are set to produce 13psi, you hit that button 3x and you're making 21psi!

I couldn't trust myself with that ability... so I just taped that wire off and did not connect it to anything. If I want to turn up the boost, I have to stop and think first and re-program one of the A/B settings in the controller in order to do so.

I couldn't trust myself with that ability... so I just taped that wire off and did not connect it to anything. If I want to turn up the boost, I have to stop and think first and re-program one of the A/B settings in the controller in order to do so.

PR, the example you provided is a little simplified, where the efficiency of the turbine at what RPM against what compressor wheel plays a lot into the pressure in the manifold vs. the pressure in the pipes. But yes, that's the idea. CO2 is amazing though. Instead of working around your spring pressure, the spring pressure is working around you.

As far as the 2X spring pressure example, I find it to be a decent guideline, but completely false as far as a rule. I work on Neons often, and right from the factory, the SRT4 uses a 4psi spring pressure, but makes anywhere from 12-14psi at the manifold. I myself ran an 8psi spring in a mitsu turbo up to 28psi.

The spring pressure not being able to hold back the pressure differential also has to take into account the area of the wastegate diaphragm vs. the valve area. So if the valve is 1/3 the size of the diaphragm, the pressure differential must exceed the spring pressure by a factor of 3 to prematurely crack.

As far as the 2X spring pressure example, I find it to be a decent guideline, but completely false as far as a rule. I work on Neons often, and right from the factory, the SRT4 uses a 4psi spring pressure, but makes anywhere from 12-14psi at the manifold. I myself ran an 8psi spring in a mitsu turbo up to 28psi.

The spring pressure not being able to hold back the pressure differential also has to take into account the area of the wastegate diaphragm vs. the valve area. So if the valve is 1/3 the size of the diaphragm, the pressure differential must exceed the spring pressure by a factor of 3 to prematurely crack.

a few cars in this thread gitting wacked!

just sayin.

Lol.

Sent a pm for tru-boost gaugeLoving these T/A builds.

If your looking for a good price on an AEM TRU-boost they are on sale through the 20th. Shoot us an email for more info

[email protected]

Lol.

Scamble boost is for adding 3psi at a push of a button. You can hit the button 3x and have 9 additional psi added to your spring+controller psi. So if your spring and controller are set to produce 13psi, you hit that button 3x and you're making 21psi!

I couldn't trust myself with that ability... so I just taped that wire off and did not connect it to anything. If I want to turn up the boost, I have to stop and think first and re-program one of the A/B settings in the controller in order to do so.

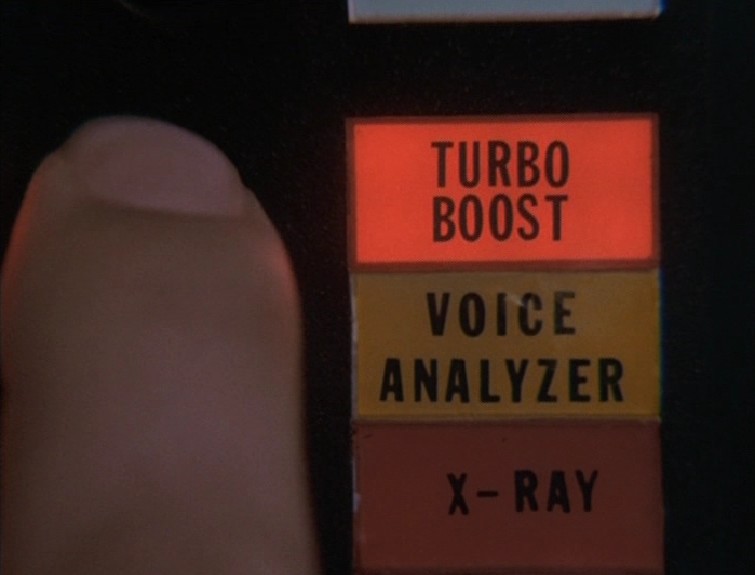

What you don't want a button in your car like this?

I picked up a tru-boost controller from SinisterDD. I also bought some more gaskets and replacement oil/cam position sensors. They didn't look to good coming out.

i thought the scramble boost was a toggle switch where you set it's duty cycle to whatever. So if I'm at 8lbs at a dc of 25% but want to set the scramble boost to 55% duty cycle and could net me 13lbs. All of those are hypothetical numbers, but I thought that is how it worked. At least looking at this video is how it seems to work

Well got another dumb question about tuning. I only have one bung on my DP that I was going to use for my wideband gauge. Does the car need to read that at all to run? Sorry, don't know much about the PCM side of it. Just occurred to me that I'm going from 4 o2 sensors to 0 if I'm using my wideband gauge off of the only bung hole available.

I'm guessing if brandon does a speed density tune then this might not be an issue, right?

Sorry, i know very little about tuning. Just trying to piece things together

I'm guessing if brandon does a speed density tune then this might not be an issue, right?

Sorry, i know very little about tuning. Just trying to piece things together

Speed density vs open/closed loop are seperate items.

You can have

SDOL

SDCL

MAFOL

MAFCL

If you only have 1 bung then put your wideband in it and tune the car for open loop

Would you perfer an additonal bung for on of the o2 sensors as well? Shouldn't be a big deal to weld one in if it means a more reliable tune.

Thread Info

-

586Replies

-

57KViews

-

Participants list