Install the TCG app

how_to_install_app_on_ios

follow_along_with_video_below_to_see_how_to_install_our_site_as_web_app

Note: this_feature_currently_requires_accessing_site_using_safari

-

💡 Fun fact. Whenever you start a thread, TCG Mechanic 5000 (our AI bot) will reply to you to start helping. It doesn't know everything and it will struggle with more complex questions but it can get the thread going and provide valuable information. You can choose to disable it prior to submitting a thread.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?When my kit was built, it was pressure tested to 35psi, in my own garage, with ZERO leaks.

Do you want a medal?

What the hell is the point of sharing anything on here if it becomes a pissing match? I posted this as an informative thread. [MENTION=340]Eagle[/MENTION] builds better cars than AMS. Take your GT-R's to him so he can build them in his garage better than AMS does.

Clearly I've offended you for some reason. Sorry man. Just posting my experience is all. I'll leave now.

You have not offended me, I am just not sure what you are arguing. I think you didn't read the article and then made a statement to argue a point that was not being debated.

Jim give me the medal

Give me a second, I need to find some magnesium alloy to forge.

You have not offended me, I am just not sure what you are arguing. I think you didn't read the article and then made a statement to argue a point that was not being debated.

Not arguing. Stating my own experience. Didn't need to read the article, but even AFTER reading the article, I'll stand firm with the results from my own experience, experimentation and results.

Checked out the breeze site and thought those were interesting.

My oem clamps from my turbo to manifold are a worm style but not a traditional one. Has raised threading instead of cut outs.

Checked out the breeze site and thought those were interesting.

My oem clamps from my turbo to manifold are a worm style but not a traditional one. Has raised threading instead of cut outs.

Yup, same as.lower rad hoses on 6.0s

"Over our 10 plus years I get this question all the time. Why don't you use T-bolt clamps instead of traditional worm gear clamps.

The answer is that when coupled with the right sized pipe, the right silicone coupler, a proper beaded end for that pipe and a high quality clamp you will actually get a better sealing area. In addition T-bolt clamps can often distort or crush most aluminum piping causing a bad seal.

Omega is a perfect testament of this as despite how much boost we throw at it we have never lost a pipe or popped off a coupler."

T-bolts vs Traditional Clamps... An explanation - Engine - GT-R Life

"Thanks for posting that Ian!

We have used just about everything (T-bolt, Murray Constant tension, etc etc) and the worm gear clamp we use we have found to be the best option. If you are stripping a worm gear clamp you are either tightening them too much or using a POS clamp. Also if you are "cutting" into the material you are clamping on as Doug eluded to you are using a crappy coupler or again over tightening it.

The pipe design is just as if not MORE important than the clamp. Use a high quality worm gear clamp with a good bead roll and you will be fine.

Omega has seen over 40psi on many occasions without a single issue. Our old EVO VIII saw over 50psi for two years.

Eric"

Something as basic as clamps. - DIY, Maintenance, Technical Support - Nissan GT-R Heritage

The answer is that when coupled with the right sized pipe, the right silicone coupler, a proper beaded end for that pipe and a high quality clamp you will actually get a better sealing area. In addition T-bolt clamps can often distort or crush most aluminum piping causing a bad seal.

Omega is a perfect testament of this as despite how much boost we throw at it we have never lost a pipe or popped off a coupler."

T-bolts vs Traditional Clamps... An explanation - Engine - GT-R Life

"Thanks for posting that Ian!

We have used just about everything (T-bolt, Murray Constant tension, etc etc) and the worm gear clamp we use we have found to be the best option. If you are stripping a worm gear clamp you are either tightening them too much or using a POS clamp. Also if you are "cutting" into the material you are clamping on as Doug eluded to you are using a crappy coupler or again over tightening it.

The pipe design is just as if not MORE important than the clamp. Use a high quality worm gear clamp with a good bead roll and you will be fine.

Omega has seen over 40psi on many occasions without a single issue. Our old EVO VIII saw over 50psi for two years.

Eric"

Something as basic as clamps. - DIY, Maintenance, Technical Support - Nissan GT-R Heritage

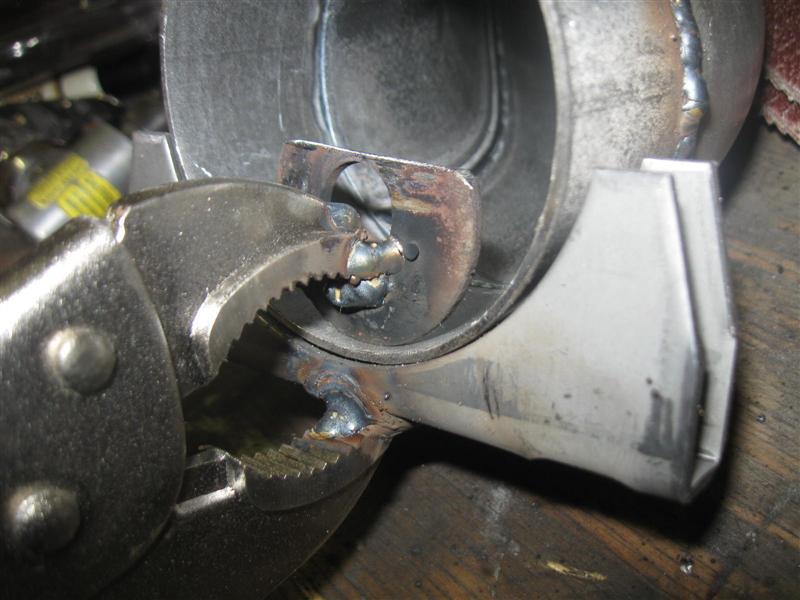

Well, go ahead and modify your charge pipes to accept a clamp that isn't specd for the purpose. I'll just continue to do nothing what so ever but brake clean the surfaces and impact on t bolt clamps and worry not

Use something like this just to be safe.....

Show me a worm clamp that'll hold that connection @42 psi

lmao ams performance shop car does

One of the most expensive builders when it comes to GT-R is pushing cheaper worm clamps?

Makes zero sense.

I have no idea y u guys are bitching about worm clamps vs t bolt clamps.. one of the biggest problems with the t bolt clamp and I'm sure most of us have done is over tightening a t bolt clamp onto this aluminum tubing which results in crushing the tubing. now if I were ams and building kits like they do I would put worm clamps in every kit to. reason being its way harder to over tighten a worm clamp and smash the tubing... oh and if people are that worried about a clamp then shell out the cash for wiggins clamps and be done with it...

I have no idea y u guys are bitching about worm clamps vs t bolt clamps.. one of the biggest problems with the t bolt clamp and I'm sure most of us have done is over tightening a t bolt clamp onto this aluminum tubing which results in crushing the tubing. now if I were ams and building kits like they do I would put worm clamps in every kit to. reason being its way harder to over tighten a worm clamp and smash the tubing... oh and if people are that worried about a clamp then shell out the cash for wiggins clamps and be done with it...

I think you are misreading me. I made this thread to educate people on something that I was informed about. Then people got on their T-Bolt high horse suggesting what I posted from AMS is nonsense.

I think you are misreading me. I made this thread to educate people on something that I was informed about. Then people got on their T-Bolt high horse suggesting what I posted from AMS is nonsense.

actually wasn't intended toward u really... mostly ctcdeezul.. he shows a cast aluminum part with 2 tbolt clamps... I guarantee if he pulls that part off and measures the wall thickness its either 1/8 or 3/16th thick.. cast wont deform like aluminum tubing will..

Quoted some stuff as I was reading and some of it was covered already. But anyways...

If you are deforming the pipe you are either using thin wall / junk material tubing or tightening the clamp too much.

I think people like t bolts because they strip or ruin worm style clamps when trying to tighten the clamp too much.

May times the tubing finish and/or the type of coupler being used is the problem. I see guys polish the aluminum and stainless tubing. That is not an ideal surface for the coupler to grip. I have seen cheap couplers that are made of a material that is hard. They don't grip the surface of the pipe well at all.

Rolling/pressing a bead in the tubing is a huge help. Eastwood and other tool companies make a nice bench top version that is about $150 and works well. You can even buy a cheap hand tool that works well enough for the home mechanic to be able to do this. Hell I have seen guys make their own tool that worked well enough. Bead rolling the tubing should be a no brainer.

Using a strap to hold one tube to another helps reduce the forces trying to separate two tubes as well. So the coupler and clamp have less work to do. It isn't uncommon to see people use these as well as bead rolling the tubing. Especially since a small strip of metal, two bolts (or studs), two lock washer and two nuts are all that is needed.

The issue with the lined worm clamps is the small surface area where the worm gear and slots in the strap provide. It is only the thickness of the strap, which isn't much. These end up deforming, slipping and stripping. Another reason people prefer t bolts over worm gears. But like you later mentioned there are the ones where the strap has a raised section where the worm gear rides. Allowing for greater contact area and a better working clamp.

Price is always a consideration. If it wasn't everyone would have V bands, Marmon or wiggens clamps on every thing they own.

I think Steve was also hinting that the part of the reason AMS uses worm clamps is so the customers can't crush the tubing by over tightening them. If they can't crush the tubing they don't have to worry about replacing anything. If they design the kit well enough they should be able to use a good worm gear clamp and have less worries about customer issues.

I do not see the point in spending money on T-Bolts and possibly deform the pipe, when I can bead the ends and run good worm drives at a fraction of the cost.

If you are deforming the pipe you are either using thin wall / junk material tubing or tightening the clamp too much.

I think people like t bolts because they strip or ruin worm style clamps when trying to tighten the clamp too much.

May times the tubing finish and/or the type of coupler being used is the problem. I see guys polish the aluminum and stainless tubing. That is not an ideal surface for the coupler to grip. I have seen cheap couplers that are made of a material that is hard. They don't grip the surface of the pipe well at all.

Rolling/pressing a bead in the tubing is a huge help. Eastwood and other tool companies make a nice bench top version that is about $150 and works well. You can even buy a cheap hand tool that works well enough for the home mechanic to be able to do this. Hell I have seen guys make their own tool that worked well enough. Bead rolling the tubing should be a no brainer.

Using a strap to hold one tube to another helps reduce the forces trying to separate two tubes as well. So the coupler and clamp have less work to do. It isn't uncommon to see people use these as well as bead rolling the tubing. Especially since a small strip of metal, two bolts (or studs), two lock washer and two nuts are all that is needed.

They make lined worm clamps that will not chew up couplers. Don't buy auto parts store garbage.

The issue with the lined worm clamps is the small surface area where the worm gear and slots in the strap provide. It is only the thickness of the strap, which isn't much. These end up deforming, slipping and stripping. Another reason people prefer t bolts over worm gears. But like you later mentioned there are the ones where the strap has a raised section where the worm gear rides. Allowing for greater contact area and a better working clamp.

Price is only one aspect of the equation and it is not even the main point. Price does not keep boost in the pipe.

Price is always a consideration. If it wasn't everyone would have V bands, Marmon or wiggens clamps on every thing they own.

I think you are misreading me. I made this thread to educate people on something that I was informed about. Then people got on their T-Bolt high horse suggesting what I posted from AMS is nonsense.

I think Steve was also hinting that the part of the reason AMS uses worm clamps is so the customers can't crush the tubing by over tightening them. If they can't crush the tubing they don't have to worry about replacing anything. If they design the kit well enough they should be able to use a good worm gear clamp and have less worries about customer issues.

I think Steve was also hinting that the part of the reason AMS uses worm clamps is so the customers can't crush the tubing by over tightening them. If they can't crush the tubing they don't have to worry about replacing anything. If they design the kit well enough they should be able to use a good worm gear clamp and have less worries about customer issues.

that's basically what I was trying to say... not to mention its also easy to find worm clamps anywhere and everywhere if u need to replace one..

that's basically what I was trying to say... not to mention its also easy to find worm clamps anywhere and everywhere if u need to replace one..

Exactly.

Also worth mentioning the width of the band is something to be looked at as well. The wider the clamp band the better.

Thread Info

-

136Replies

-

9KViews

-

Participants list