I ran the truck in that configuration for a few years and thoroughly enjoyed it, beating it like a redheaded stepchild, doing burnouts and acting like a 17 year old regularly.

I made a few changes over time, adding rack and pinion steering and a big front sway bar, NTC Stage 3 4L80/FTI 3700 converter and lots of gas/rear tires.

Then I took it back up to Nate to put exhaust on, again, more stainless, this time he built a y pipe going into 3" Dynomax Ultraflows. Much more bearable than the open down pipe.

Eventually the rust on the cab floor started to take its toll on the cab mounts. It got to the point that the doors didnt want to close right so it became apparent that I needed to do something.

So, off came the front clip and cab.

One of our design engineers at work has a brother that runs a rod shop up in the northern part of the state, Hilltop Hot Rods. After some conversations I took the cab up to him to install a 1 piece cab floor, outer rockers, cab corners, door bottoms, repair any other rot he might find, smooth the firewall and bodywork/paint the interior of the cab.

I also him Lizard Skin the inside of the doors, both sides of the cab floor and the inside of the firewall/rear of the cab. I want this thing quiet inside.

My original plan was to do a quick hotsy wash and por15 the chassis and plunk the cab and clip back on and get back to enjoying it.

Then a friend hooked me up with his buddy that was just opening a powder coat shop - he quoted me 500 to blast and powder coat the entire rolling chassis.

So, naturally, apart everything came. I didn't take any pictures of that part of the process unfortunately.

Since it was apart I figured we might as well replace the bed floor as it had some rust.

Once we got the bodywork done and paid for I turned my attention to the chassis and suspension.

The old static drop stuff went on the Facebox and I installed Dominator D2600 bags, Accuair ELevel system and a pair of Viair 480 compressors on 2 4 gallon tanks that fit between the frame rails out back.

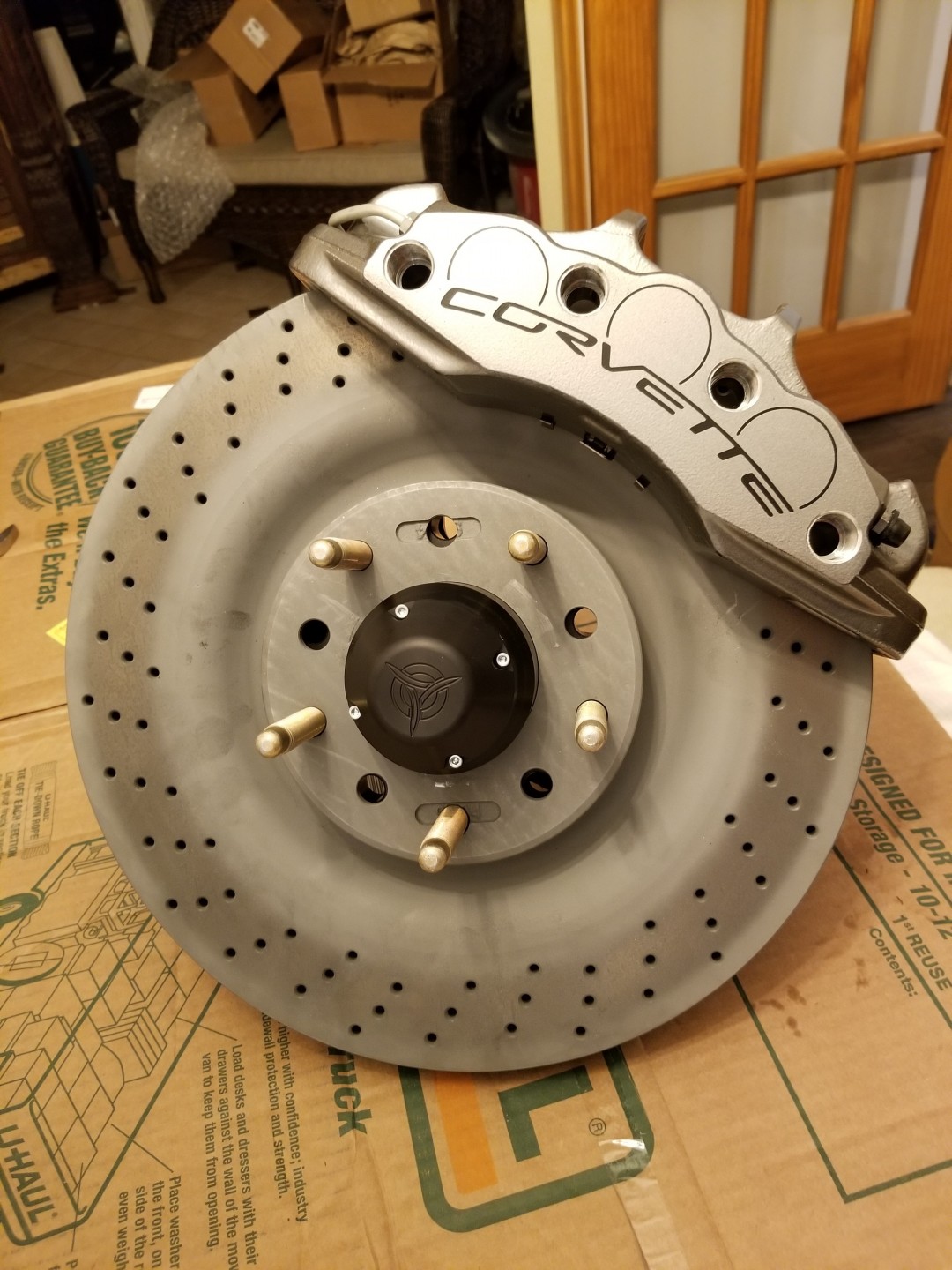

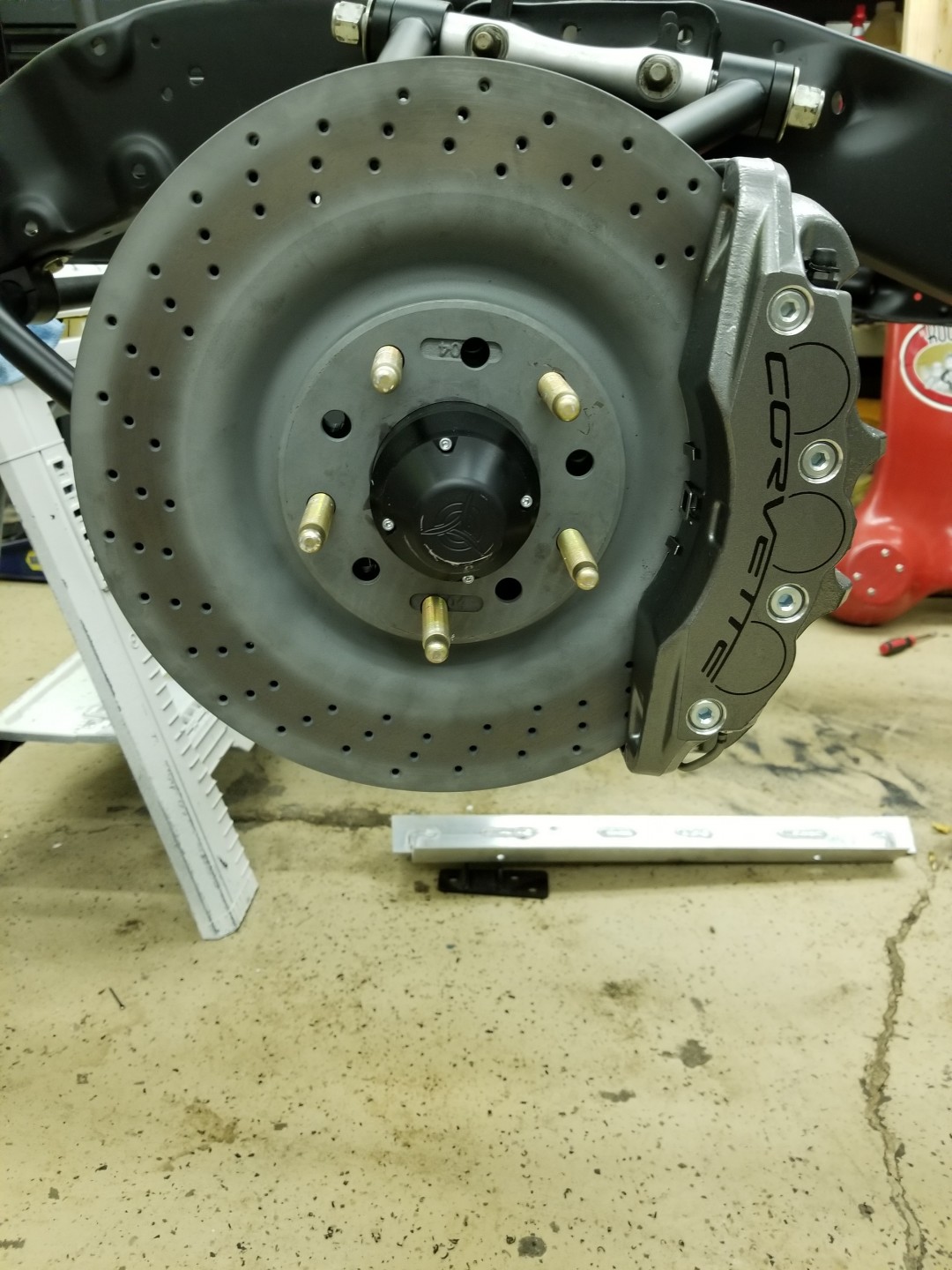

For brakes I was really leaning towards some Baer monoblock 6 pistons up front and 4 piston rears. Then I did some more reading and talked to some friends that do brake engineering for the OEM's and they turned me onto Kore3 systems that adapt C6Z components to the modular spindle systems that CPP makes.

They claim much higher quality and performance. Plus it was about a grand cheaper.

That checked all the boxes I needed - higher quality, easier parts to find and lower cost. Plus Tobin at Kore3 is absolutely amazing to deal with. Tons of knowledge and very willing to share it.

The new brakes were going to require me to buy new wheels so I started doing lots of looking and debating on what to run. The debate between Billet Specialties and Intro's was a real struggle.

Then I came across this truck that Boris @ Street Machinery had put together and instantly chubbed on the rear wheels.

After talking to him some it became apparent that I was going to have to narrow the rear end to run them.

Well, shit. I already had had the stock housing powder coated. So, after some debate I made the decision to just have a 9" built for the truck. I figured if I turn the wick up that the 12 bolt would be marginal and fuckit, I've come this far.

So, a call to Quick Performance in Ames netted me a 35 spline nodular 9" with a Detroit and 3.50 gear.

Once I got that slapped in the chassis and everything back down on 4 wheels I plugged the drivetrain back in it and took the chassis up to be mated with the cab and bed.

That was earlier this past spring, once he got that stuff on and bolted down I brought the truck back home to finish installing the turbo system and hang the vintage air stuff.

Once I got it to that point I took it back up to the shop to have him hang the front clip, plumb brake lines/air ride lines and if my cash holds out have him wire it.

That's about where we are at right now.

Once he gets done with it up there I'll be bringing it home, finishing plumbing the fuel system, finish wiring in the Dakota Digital dash and tidying things up.

While I do those things on the cheap I'll be saving my pennies for interior.

That's the next debate, the truck has always had the OG bench in blue/black houndstooth. But, I did pick up a really nice full set of K5 Blazer buckets/console a few years back. Do I have the bench recovered? Do I have the buckets and console redone? If I go that route I'll put stock reproduction trim parts - door panels, armrests, etc...in it.

Or do I take it to a shop and have them put a badass custom leather interior in it?