The year was 2017, I had just watched The Smoking Tire's episode with Karl Muth's LS & gated T56 swapped Jaguar XJ8

He said "if you wanted to you could build a car like this for about $35,000 in parts"

I said "I could probably do it for $3,500 and about 4 months of work" (note: I was wrong... so very very wrong)

I got in contact with Jaguar Specialties, a company in CA that specializes in Jaguars (duh). The guy sells kits to Chevy 350, LT1, and LS swap various years of Jaguar from the 60s to 2003. All his kits are CARB legal. I asked about the LS kit and he mentioned what it included and I would need to buy some off the shelf parts locally to save on shipping. The kit is fairly comprehensive and includes most of what you need. The advantage of the kit (and bulk of the cost) is because he includes a CAN module loaded with his software that allows the LS PCM to work with the Jaguar CAN network.

I started this project in 2017. In April I tracked down a 1998 LS1/4L60E for $1500 on Craigslist, I offered the guy $1200 and he said "okay".

Only after I bought it did I realize the perimeter head LS1s were basically the least desirable ones, because they have so many 2 year only parts.... and I should have held out and bought one that was not missing 80% of the front accessories.

In July I bought a 1999 XJ8 with a dead transmission and a bunch of questionable engine repairs for $800. This didnt matter, because it was all coming out.

Here it is when I brought it home, next to Adequately Sized Red, my former 1982 Ford F100 with a 3.8 liter V6 and Three on the Tree.

Since I had other things to do it continued to sit for a few months, and then it was winter... so I couldnt do anything outside since I hate the cold.

It was a base model XJ8, with base model interior and the drivers seat looked like someone had ripped it up and then covered it with glossy paint. So over winter I recovered the front two seats with used seat covers from the UK, and then redyed the interior. I also sourced some Vanden Plas tables and a VdP shift knob and steering wheel.

Once I recovered the seats the tone didnt match anymore.... so then I redyed them in the basement with cheap ebay dye (that I had to buy 4 bottles of because I kept running out). Once the weather warmed up I was able to install them.

During this time I also installed a Texas Speed 224R cam with upgraded valve springs when I could get out to the garage. (which I cant find any pictures of, of course)

Once Spring came I was able to get out into the garage without needing to run the heater and started the fun part. Pulling the dead drivetrain in a garage barely bigger than the car that was built in the 1920s with a chimney in the middle of it.

To pull the engine I had to have the car 1/2 way in the garage, then once the engine was high enough I had to push the car all the way out the door.

In spring of 2018 I got the factory 4.0 liter DOHC V8 out. Despite being only a 4.0 liter (or "litre") the engine is massive. It is much larger than the LS.

With the Jaguar engine out it was time to stab the GM lump in. Ignore the red Amazon plug wires, one of those broke before I even got the engine started.

I thought getting the engine in was going to be the hard part... little did I know that I still had about 75% of the work left to do, but once it was in I could actually fit the car in the garage.... barely.

The absolute worst part, and the one where I made my biggest mistake, was the wiring. Stupidly I thought "oh, the engine was from a 1998 Camaro SS so I'll buy a 1998 Camaro SS harness and PCM". I found one on ebay for a deal, $350 for everything.

Then I found out its nearly impossible to tune the 1997-1998 PCMs.... and the wiring harness is different than the 99+ harnesses.

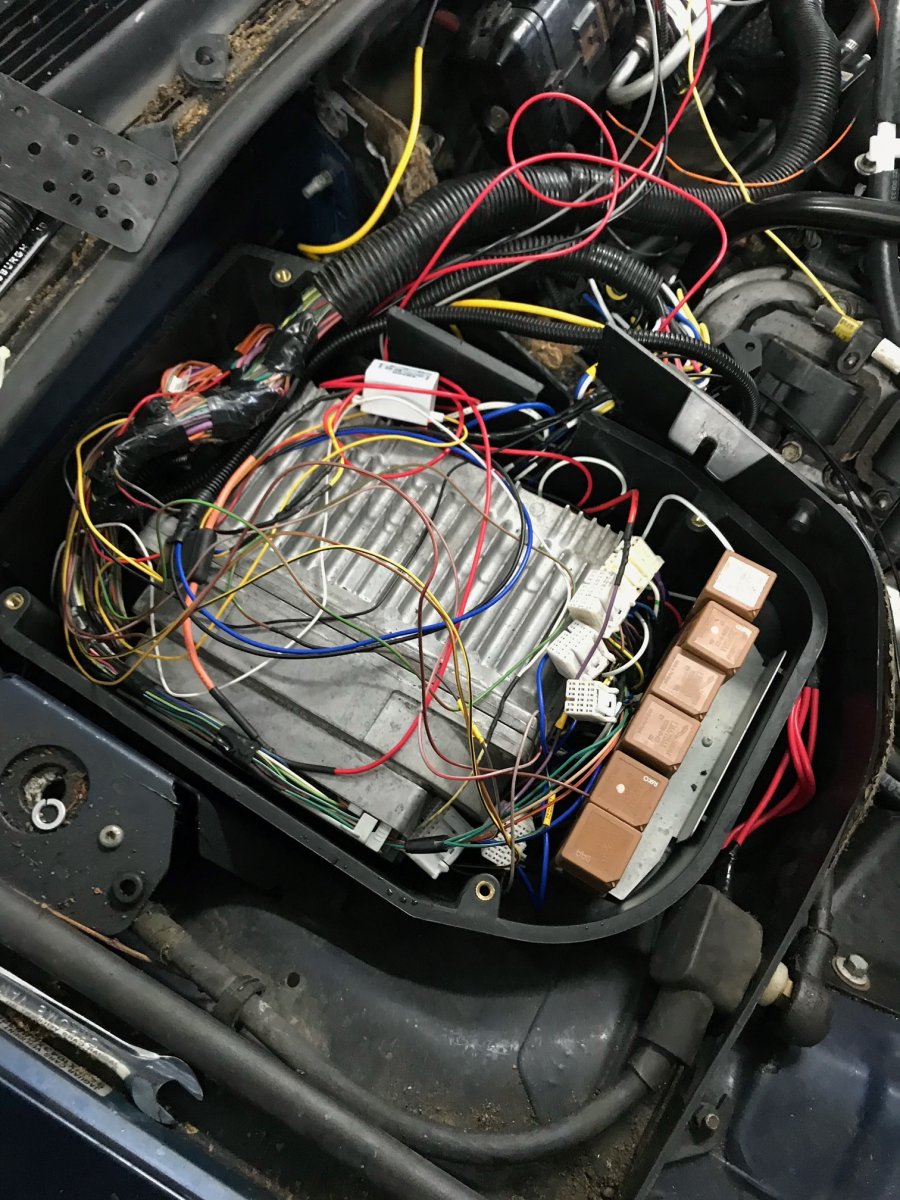

The Jaguar ECU and TCU are contained in a small sealed area on the passenger side of the car. The wiring was pretty easy but still tedious. I think only 10 to 15 connections needed to be made to get the Jaguar Specialties module to work with the GM PCM and the Jaguar CAN network... but it was "connect this wire to the Jaguar's CAN harness High and this wire to the CAN harness Low".... then "connect these two wires with a jumper"... and "make a harness for the reverse light switch, then connect it to this other wire"... At one point I had about 10 pages of wiring diagrams spread out. All because Jaguar changed their wiring colors, and sometimes pin positions, every 2 years over the XJ8's build (from 1998-2003).

Once I had the 1998 PCM and harness hooked up I was able to actually fire it up (with open manifolds, because I had to make the whole exhaust). Jaguar thoughtfully gave me this error because I hadnt hooked up the CAN module correctly. The British - masters of the obvious.

Wiring saga - part 2.

So... since I bought the 1998 PCM I tried to find someone to tune it for the Texas Speed 224R cam and the 2200 stall, plus do something about some of those pesky readiness monitors that would give me issues later on. (again, I will point out this kit can be made to be CARB legal in CA, so the CAN module and PCM can work together to control things, even like the EVAP solenoid... I just... didnt go that route)

Anyway, every single tuner refused because those PCMs can and will brick and they're done. This meant I had to buy a 1999+ PCM and then REPIN ALL THE PCM CONNECTIONS.

Had I just bought a 1999+ harness in the first place I would have saved myself about 2 weeks of work (I work slow and I'm lazy).

The wiring can be described as "rats nest". Dont worry, the wiring gets worse.

Once it ran and drove, but I didnt have the throttle cable hooked up or any form of exhaust other than open manifolds, my wife and I decided to move across town. So I had to hook a long piece of wire up to the throttle body and operate that by hand out the window while driving it up onto the Uhaul trailer.

As much fun as that was, it was worth it... because I went from a 2 car garage with a single 8ft door... to a 1440 square foot garage that was divided into a 26x30 size, a single car side (for my wife), 2 storage rooms and a loft... with 10ft ceilings (and a flooding issue, that the seller didnt disclose).

In the new garage I buttoned things up. I appologize I dont have many pictures because 90% of this work is small menial jobs. Like hook up a PCV system, or hook up the throttle cable, and route the cooling hoses and AC lines. Plus the maker of the kit is protective of his IP rights and does not want pictures of parts from the kit published... so I am respecting his wishes.

I do have pictures of the driveshaft solution somewhere and I will add those when I find them. Basically in the kit he says to modify the factory Jaguar 2 piece driveshaft by cutting it and flipping some parts around and welding it back together. No driveshaft shop around here would touch it. The factory Jaguar diff uses one of those rubber guibo disks.... I ended up buying an aluminum adapter to go from the Jaguar guibo style flange to a standard bolt on u-joint.... then I figure out that the required distance was the same length as a Chevy Avalanche driveshaft... so driveshaft from the junkyard, a couple of adapter u-joints, the correct 4L60E slip yoke and I made my own driveshaft.

Next to the wiring the most time consuming and physically demanding job was the exhaust. Which was a Jegs 2 and 1/4 inch "exhaust in a box" and 2 knock off Jegs Flowmasters

Pictured - my non professional welding and my "cut a piece and weld every 2-3 inches" passenger side down pipe. The drivers side is worse... it looks like 3/4 of a corkscrew to get around the steering shaft.

Exhaust tip vs factory.

After crawling under the car for the 400th time and eyeballing the next section of exhaust I got a little bored with the welder.

But... the exhaust was "finished" (it still leaks, because I used clamps instead of flanges between the sections)

And with the exhaust finished that means the car was "finished" (for now).

Heres the LS in its new home, with my cheap home made intake.

After finishing it the car drove great and I drove it frequently in summer. One minor incident pulled a section of the exhaust off in a Taco Bell parking lot, but I was able to shove it back together and get it home.

The exhaust has some leaks between the clamps, the trans shifts a little hard, some of the cobbled together lines drip a little fluid. Theres a slow coolant leak somewhere too. The mufflers drone like crazy at 70mph.

But the car drives.... and it goes like a scalded cat.

All in all - I think I spent around $7500. I bought many parts I didnt need, and the debacle with the wiring harness probably cost me $500 more than it should have. If I bought just a junkyard 5.3, didnt reseal anything, didnt put in a cam, and hooked up the exhaust to any of the factory Jaguar exhaust then I could have probably gotten this done for around $3,500.

But wait, theres more!

So after driving it for the summer of 2019 I put it away for winter. In the spring of 2020 (the cursed year). I decided to do some suspension work because there was a clunk in the back and it felt a little off.

Jaguar has an interesting solution with the famed Jaguar independent rear suspension. I always knew it looked odd but I couldnt figure it out. It turns out Jaguar developed an independent rear suspension that only uses a lower control arm on each side and thats it. It looks like it works by black magic. The way they did this is by putting u-joints in the axles instead of CV joints and essentially making the axles act as the upper control arms. This causes the center diff to be under compression all the time.

A side effect of this is they couldnt use rubber bushings in the wheel knuckles, so they had to use tapered roller bearings, and they can wear and cause a clunk. So Jaguar uses a 10 inch long eccentric bolt and 2 opposing tapered roller bearings in the bottom of the knuckle so they can align the rear and mount the knuckle to the lower control arm.

Heres the better of the two sides. It took me 4 hours to get the two bearings out of the bottom of the knuckle and bolt it back together.

Heres the side that clunked. Thats the race in the knuckle.

Heres the bearing and the $80 eccentric bolt. I had to cut through both ends because the bolt was seized in the spacer tube and the bearing seized on the end. I ended up just buying a used knuckle off ebay and some used bolts.

Heres the suspension with the knuckle removed... just a lower control arm and an axle. The shock bolts to an upper hat, and that upper hat bolts to the body... so technically you can drop the whole rear subframe with the springs still under tension.

And now - wiring part 3 - the "I'm an idiot" part.

After I got the suspension done I took it for a drive... the speedometer wasnt working and it wasnt shifting out of first. The check engine light was giving a misfire code.

I went over everything, then figured out the trans speed sensor wasnt reading.... so I made a new harness for that and bypassed the factory one. That did not fix it.

After some tech help the owner of Jaguar Specialties told me that the speedometer gets its signal from the ABS sensors and not from the GM PCM at all.... turns out the speedometer issue was because I used a sensor from a 2004 XK8 (which the replacement knuckle came from). So I swapped the ABS sensor and the speedo worked.

But it still wasnt shifting and giving me a ton of codes... I couldnt figure it out until I was messing with my PCM rats nest while the car was running and the engine just shut off.

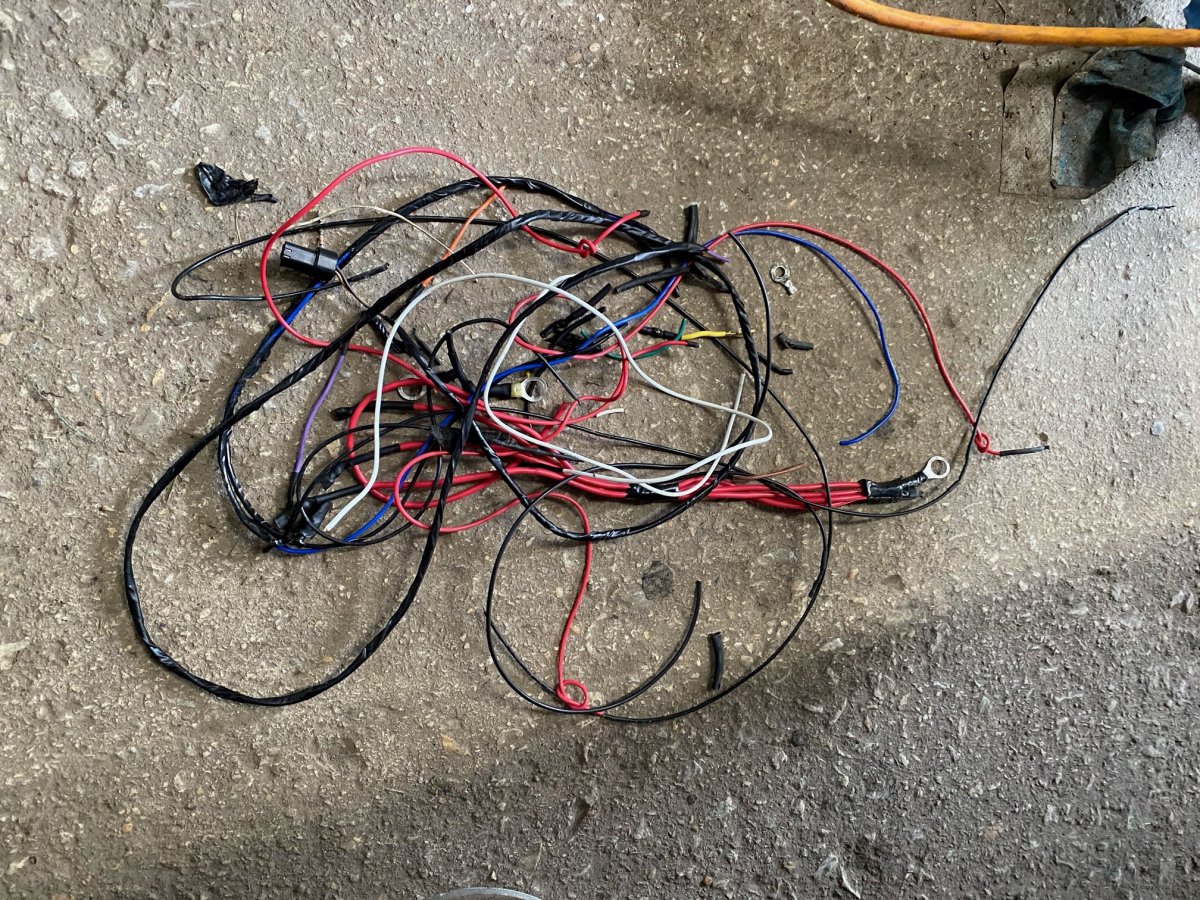

Long story short... the wiring I bought was copper coated aluminum, and the flux I used while soldering all of the connections had corroded the aluminum core.... so I had to get rid of every segment of the aluminum cored wire and replace it with new stranded 100% copper wiring... so I had to pull out and replace this (and more connections that werent pictured).

Once the wiring was fixed it has run great since then. I even got around to fixing the solder joints in the ABS module so now traction control and ABS work again.

Heres it passing emissions after putting 3,500 miles on it with some confused people wondering why the Jaguar was so loud and barely running.

Heres a clip of it idling.

And heres the little Vanden Plas tables being used for their intended purpose.... eating Popeyes chicken while on lunch break at work. Side note - after putting them in I see why Jaguar only offered these on the long wheel base Vanden Plas, they take up about 2 inches of legroom when they're folded up. They work for the Vanden Plas because those are 5 inches longer in the rear seat area.

He said "if you wanted to you could build a car like this for about $35,000 in parts"

I said "I could probably do it for $3,500 and about 4 months of work" (note: I was wrong... so very very wrong)

I got in contact with Jaguar Specialties, a company in CA that specializes in Jaguars (duh). The guy sells kits to Chevy 350, LT1, and LS swap various years of Jaguar from the 60s to 2003. All his kits are CARB legal. I asked about the LS kit and he mentioned what it included and I would need to buy some off the shelf parts locally to save on shipping. The kit is fairly comprehensive and includes most of what you need. The advantage of the kit (and bulk of the cost) is because he includes a CAN module loaded with his software that allows the LS PCM to work with the Jaguar CAN network.

I started this project in 2017. In April I tracked down a 1998 LS1/4L60E for $1500 on Craigslist, I offered the guy $1200 and he said "okay".

Only after I bought it did I realize the perimeter head LS1s were basically the least desirable ones, because they have so many 2 year only parts.... and I should have held out and bought one that was not missing 80% of the front accessories.

In July I bought a 1999 XJ8 with a dead transmission and a bunch of questionable engine repairs for $800. This didnt matter, because it was all coming out.

Here it is when I brought it home, next to Adequately Sized Red, my former 1982 Ford F100 with a 3.8 liter V6 and Three on the Tree.

Since I had other things to do it continued to sit for a few months, and then it was winter... so I couldnt do anything outside since I hate the cold.

It was a base model XJ8, with base model interior and the drivers seat looked like someone had ripped it up and then covered it with glossy paint. So over winter I recovered the front two seats with used seat covers from the UK, and then redyed the interior. I also sourced some Vanden Plas tables and a VdP shift knob and steering wheel.

Once I recovered the seats the tone didnt match anymore.... so then I redyed them in the basement with cheap ebay dye (that I had to buy 4 bottles of because I kept running out). Once the weather warmed up I was able to install them.

During this time I also installed a Texas Speed 224R cam with upgraded valve springs when I could get out to the garage. (which I cant find any pictures of, of course)

Once Spring came I was able to get out into the garage without needing to run the heater and started the fun part. Pulling the dead drivetrain in a garage barely bigger than the car that was built in the 1920s with a chimney in the middle of it.

To pull the engine I had to have the car 1/2 way in the garage, then once the engine was high enough I had to push the car all the way out the door.

In spring of 2018 I got the factory 4.0 liter DOHC V8 out. Despite being only a 4.0 liter (or "litre") the engine is massive. It is much larger than the LS.

With the Jaguar engine out it was time to stab the GM lump in. Ignore the red Amazon plug wires, one of those broke before I even got the engine started.

I thought getting the engine in was going to be the hard part... little did I know that I still had about 75% of the work left to do, but once it was in I could actually fit the car in the garage.... barely.

The absolute worst part, and the one where I made my biggest mistake, was the wiring. Stupidly I thought "oh, the engine was from a 1998 Camaro SS so I'll buy a 1998 Camaro SS harness and PCM". I found one on ebay for a deal, $350 for everything.

Then I found out its nearly impossible to tune the 1997-1998 PCMs.... and the wiring harness is different than the 99+ harnesses.

The Jaguar ECU and TCU are contained in a small sealed area on the passenger side of the car. The wiring was pretty easy but still tedious. I think only 10 to 15 connections needed to be made to get the Jaguar Specialties module to work with the GM PCM and the Jaguar CAN network... but it was "connect this wire to the Jaguar's CAN harness High and this wire to the CAN harness Low".... then "connect these two wires with a jumper"... and "make a harness for the reverse light switch, then connect it to this other wire"... At one point I had about 10 pages of wiring diagrams spread out. All because Jaguar changed their wiring colors, and sometimes pin positions, every 2 years over the XJ8's build (from 1998-2003).

Once I had the 1998 PCM and harness hooked up I was able to actually fire it up (with open manifolds, because I had to make the whole exhaust). Jaguar thoughtfully gave me this error because I hadnt hooked up the CAN module correctly. The British - masters of the obvious.

Wiring saga - part 2.

So... since I bought the 1998 PCM I tried to find someone to tune it for the Texas Speed 224R cam and the 2200 stall, plus do something about some of those pesky readiness monitors that would give me issues later on. (again, I will point out this kit can be made to be CARB legal in CA, so the CAN module and PCM can work together to control things, even like the EVAP solenoid... I just... didnt go that route)

Anyway, every single tuner refused because those PCMs can and will brick and they're done. This meant I had to buy a 1999+ PCM and then REPIN ALL THE PCM CONNECTIONS.

Had I just bought a 1999+ harness in the first place I would have saved myself about 2 weeks of work (I work slow and I'm lazy).

The wiring can be described as "rats nest". Dont worry, the wiring gets worse.

Once it ran and drove, but I didnt have the throttle cable hooked up or any form of exhaust other than open manifolds, my wife and I decided to move across town. So I had to hook a long piece of wire up to the throttle body and operate that by hand out the window while driving it up onto the Uhaul trailer.

As much fun as that was, it was worth it... because I went from a 2 car garage with a single 8ft door... to a 1440 square foot garage that was divided into a 26x30 size, a single car side (for my wife), 2 storage rooms and a loft... with 10ft ceilings (and a flooding issue, that the seller didnt disclose).

In the new garage I buttoned things up. I appologize I dont have many pictures because 90% of this work is small menial jobs. Like hook up a PCV system, or hook up the throttle cable, and route the cooling hoses and AC lines. Plus the maker of the kit is protective of his IP rights and does not want pictures of parts from the kit published... so I am respecting his wishes.

I do have pictures of the driveshaft solution somewhere and I will add those when I find them. Basically in the kit he says to modify the factory Jaguar 2 piece driveshaft by cutting it and flipping some parts around and welding it back together. No driveshaft shop around here would touch it. The factory Jaguar diff uses one of those rubber guibo disks.... I ended up buying an aluminum adapter to go from the Jaguar guibo style flange to a standard bolt on u-joint.... then I figure out that the required distance was the same length as a Chevy Avalanche driveshaft... so driveshaft from the junkyard, a couple of adapter u-joints, the correct 4L60E slip yoke and I made my own driveshaft.

Next to the wiring the most time consuming and physically demanding job was the exhaust. Which was a Jegs 2 and 1/4 inch "exhaust in a box" and 2 knock off Jegs Flowmasters

Pictured - my non professional welding and my "cut a piece and weld every 2-3 inches" passenger side down pipe. The drivers side is worse... it looks like 3/4 of a corkscrew to get around the steering shaft.

Exhaust tip vs factory.

After crawling under the car for the 400th time and eyeballing the next section of exhaust I got a little bored with the welder.

But... the exhaust was "finished" (it still leaks, because I used clamps instead of flanges between the sections)

And with the exhaust finished that means the car was "finished" (for now).

Heres the LS in its new home, with my cheap home made intake.

After finishing it the car drove great and I drove it frequently in summer. One minor incident pulled a section of the exhaust off in a Taco Bell parking lot, but I was able to shove it back together and get it home.

The exhaust has some leaks between the clamps, the trans shifts a little hard, some of the cobbled together lines drip a little fluid. Theres a slow coolant leak somewhere too. The mufflers drone like crazy at 70mph.

But the car drives.... and it goes like a scalded cat.

All in all - I think I spent around $7500. I bought many parts I didnt need, and the debacle with the wiring harness probably cost me $500 more than it should have. If I bought just a junkyard 5.3, didnt reseal anything, didnt put in a cam, and hooked up the exhaust to any of the factory Jaguar exhaust then I could have probably gotten this done for around $3,500.

But wait, theres more!

So after driving it for the summer of 2019 I put it away for winter. In the spring of 2020 (the cursed year). I decided to do some suspension work because there was a clunk in the back and it felt a little off.

Jaguar has an interesting solution with the famed Jaguar independent rear suspension. I always knew it looked odd but I couldnt figure it out. It turns out Jaguar developed an independent rear suspension that only uses a lower control arm on each side and thats it. It looks like it works by black magic. The way they did this is by putting u-joints in the axles instead of CV joints and essentially making the axles act as the upper control arms. This causes the center diff to be under compression all the time.

A side effect of this is they couldnt use rubber bushings in the wheel knuckles, so they had to use tapered roller bearings, and they can wear and cause a clunk. So Jaguar uses a 10 inch long eccentric bolt and 2 opposing tapered roller bearings in the bottom of the knuckle so they can align the rear and mount the knuckle to the lower control arm.

Heres the better of the two sides. It took me 4 hours to get the two bearings out of the bottom of the knuckle and bolt it back together.

Heres the side that clunked. Thats the race in the knuckle.

Heres the bearing and the $80 eccentric bolt. I had to cut through both ends because the bolt was seized in the spacer tube and the bearing seized on the end. I ended up just buying a used knuckle off ebay and some used bolts.

Heres the suspension with the knuckle removed... just a lower control arm and an axle. The shock bolts to an upper hat, and that upper hat bolts to the body... so technically you can drop the whole rear subframe with the springs still under tension.

And now - wiring part 3 - the "I'm an idiot" part.

After I got the suspension done I took it for a drive... the speedometer wasnt working and it wasnt shifting out of first. The check engine light was giving a misfire code.

I went over everything, then figured out the trans speed sensor wasnt reading.... so I made a new harness for that and bypassed the factory one. That did not fix it.

After some tech help the owner of Jaguar Specialties told me that the speedometer gets its signal from the ABS sensors and not from the GM PCM at all.... turns out the speedometer issue was because I used a sensor from a 2004 XK8 (which the replacement knuckle came from). So I swapped the ABS sensor and the speedo worked.

But it still wasnt shifting and giving me a ton of codes... I couldnt figure it out until I was messing with my PCM rats nest while the car was running and the engine just shut off.

Long story short... the wiring I bought was copper coated aluminum, and the flux I used while soldering all of the connections had corroded the aluminum core.... so I had to get rid of every segment of the aluminum cored wire and replace it with new stranded 100% copper wiring... so I had to pull out and replace this (and more connections that werent pictured).

Once the wiring was fixed it has run great since then. I even got around to fixing the solder joints in the ABS module so now traction control and ABS work again.

Heres it passing emissions after putting 3,500 miles on it with some confused people wondering why the Jaguar was so loud and barely running.

Heres a clip of it idling.

And heres the little Vanden Plas tables being used for their intended purpose.... eating Popeyes chicken while on lunch break at work. Side note - after putting them in I see why Jaguar only offered these on the long wheel base Vanden Plas, they take up about 2 inches of legroom when they're folded up. They work for the Vanden Plas because those are 5 inches longer in the rear seat area.

Sorry about that. So since you had the 60 were you able to tie the shifter in or did you have to go aftermarket?

Sorry about that. So since you had the 60 were you able to tie the shifter in or did you have to go aftermarket?