I've recently scored a couple deals on parts that I wasn't expecting to install for a while even if I had everything I needed.

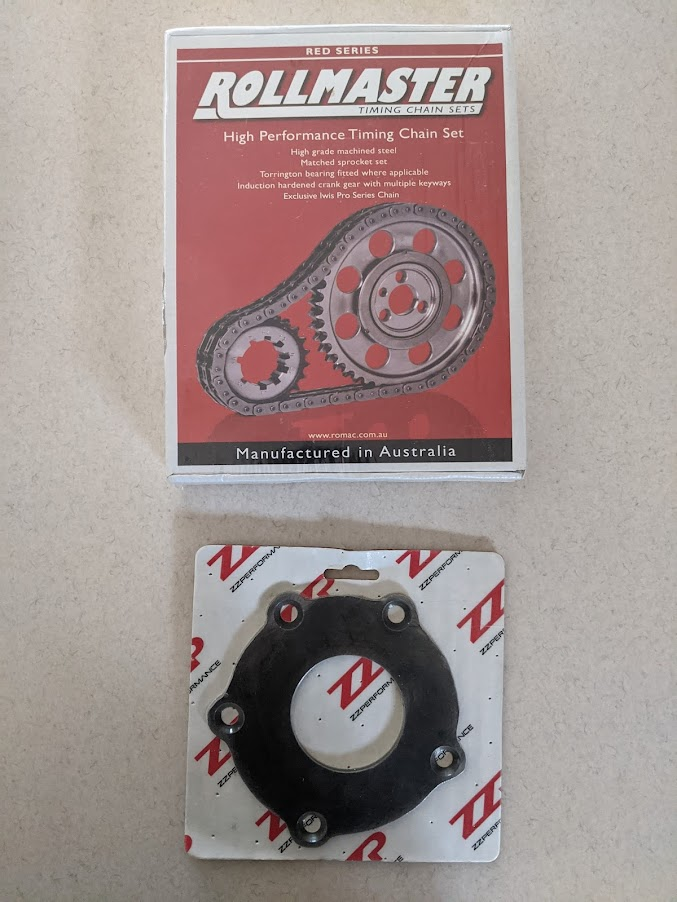

Got these for $110 shipped.

And this for $275. It's never been installed!

I already have the modified retainers and fancy valve locks in the car, but I'm a little unsure of what else I'm going to need. It seems like stock LS7 is the best option for lifters, but what about valve springs? I know the LS6 springs will be much too weak for this cam. I see ZZP recommends their 136 or 150lb springs but which one is better for which application?

Then there's the pushrods. Since I'm not planning to install the cam and lifters without L67 head gaskets or ARP studs, I have a few potential variables working on the length. What is the preferred way to check what size I need? I have a length checker tool, but I don't entirely understand how I'm supposed to use it because I never had much of a feel for lifter preload. I's this tool more geared toward solid lifter engines? I've always just torqued my rockers to the torque spec and made sure that the bolt wasn't being turned more than 1.5 turns past zero lash. ? I figure that a little machinist's blue on the valve tip and checking the contact area with stock pushrods would give me a clearer indication of what needs to happen.

I figure that a little machinist's blue on the valve tip and checking the contact area with stock pushrods would give me a clearer indication of what needs to happen.

I'm probably just leaving my balance shaft in the block and removing the gear. I have a cam bearing install tool so I'd have no problem installing the 440 bearings clocked 180 out, but I also have no intentions of pulling this engine out of the car until it blows. I don't see a proper balance shaft delete happening in the car. Does the gear come off with a puller? I've never removed one, and it's already gone in my spare engine.

I have this thin oil pump cover, so that's cool. Does anybody know the secret to ZZP's "extra thick" timing cover gasket? I feel like I've already been screwed by their "high flow" fuel filter being one of the cheapos from Rock Auto. Sure they did their testing, but can they just tell me the part number since it's not actually theirs? I assume that this gasket is the same story. Is it anything special? Is it a certain brand or material? I currently have a metal gasket in there, but their picture shows a paper one which I imagine is in fact thicker. lol

I think that's it for now, but I'm sure some answers will spark more questions.

Got these for $110 shipped.

And this for $275. It's never been installed!

I already have the modified retainers and fancy valve locks in the car, but I'm a little unsure of what else I'm going to need. It seems like stock LS7 is the best option for lifters, but what about valve springs? I know the LS6 springs will be much too weak for this cam. I see ZZP recommends their 136 or 150lb springs but which one is better for which application?

Then there's the pushrods. Since I'm not planning to install the cam and lifters without L67 head gaskets or ARP studs, I have a few potential variables working on the length. What is the preferred way to check what size I need? I have a length checker tool, but I don't entirely understand how I'm supposed to use it because I never had much of a feel for lifter preload. I's this tool more geared toward solid lifter engines? I've always just torqued my rockers to the torque spec and made sure that the bolt wasn't being turned more than 1.5 turns past zero lash. ?

I'm probably just leaving my balance shaft in the block and removing the gear. I have a cam bearing install tool so I'd have no problem installing the 440 bearings clocked 180 out, but I also have no intentions of pulling this engine out of the car until it blows. I don't see a proper balance shaft delete happening in the car. Does the gear come off with a puller? I've never removed one, and it's already gone in my spare engine.

I have this thin oil pump cover, so that's cool. Does anybody know the secret to ZZP's "extra thick" timing cover gasket? I feel like I've already been screwed by their "high flow" fuel filter being one of the cheapos from Rock Auto. Sure they did their testing, but can they just tell me the part number since it's not actually theirs? I assume that this gasket is the same story. Is it anything special? Is it a certain brand or material? I currently have a metal gasket in there, but their picture shows a paper one which I imagine is in fact thicker. lol

I think that's it for now, but I'm sure some answers will spark more questions.