Install the TCG app

how_to_install_app_on_ios

follow_along_with_video_below_to_see_how_to_install_our_site_as_web_app

Note: this_feature_currently_requires_accessing_site_using_safari

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3800 4T80E>4t60/65/hd

- Thread starter Turbocharged400sbc

- Start date

More options

Who Replied?figured side was specific but when you said over fill i didnt know if the added capacity in the bottom would help or not.

It probably would just pump it into the side case and explode out a vent or the cap. I am going to look into expanding my capacity while I've got everything apart anyway. It's been a minute since I've played with the welder, need to do something with it so I don't forget how.

It probably would just pump it into the side case and explode out a vent or the cap. I am going to look into expanding my capacity while I've got everything apart anyway. It's been a minute since I've played with the welder, need to do something with it so I don't forget how.

The bigger case is a theory. It has not been 100% proven that I ran out of fluid. But it is pretty likely they way the trans went neutral on a hard launch after a long stay spooling the torque converter. 1.3 60 foots, long spool up...

probably drained the cover enough to cause an air pocket to hit the pickup tube.

The brackets are nice. Will save a lot of time..

Thans tbc400

I figured id give you the heavier ones

you get to enjoy the awesome American made scotch I sent ya with it?

yes both are from the block to the diff cover. easy removal for FDR changes a the diff planetary

Overfill keep an eye on line pressure during a run.

I wondered about that. I barely have room for the cover as it is. Could probably add some on the bottom, but it's pretty tight from the middle on up.

It probably would just pump it into the side case and explode out a vent or the cap. I am going to look into expanding my capacity while I've got everything apart anyway. It's been a minute since I've played with the welder, need to do something with it so I don't forget how.

The bigger case is a theory. It has not been 100% proven that I ran out of fluid. But it is pretty likely they way the trans went neutral on a hard launch after a long stay spooling the torque converter. 1.3 60 foots, long spool up...

probably drained the cover enough to cause an air pocket to hit the pickup tube.

Either way, more fluid capacity always sounds like a good idea to me.

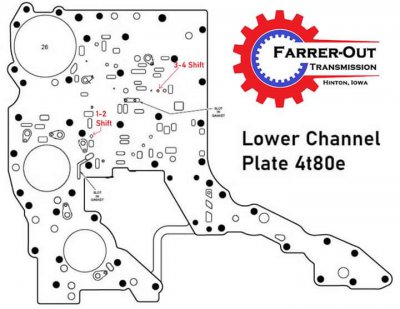

consider it confirmed....the failure related to too low of a fluid level is easily simulated by high acceleration with the 80e....

the highly aerated lower sump oil is discharged by both the scavenge pump to the forward part of the side cover where it flows down to the forward part of the pressure pump filter/pickup.

add in anything approaching a 1g launch and now all those bubbles are at the inlet filter and we all know air flows easier through that shit than fluid, voila, suck some air.

overfill it and you raise the dynamic level enough that its likely that the air bubbles take longer to get to the filter screen and causing damage at the high hydraulic load gears.

the discharge path of the rear scavenge pump isn't bad, there's plenty of volume increase and path length before it lets the oil flow upward to the discharge opening. this pump draws from the right/rear lower sump filter. it is presumably doing a lot of the side sump refilling during hard accel.

the ball buster is the forward scavenge pump.

its discharge path is short and spews downward, far closer to the filter leading edge than the rear pump. its path is very short, fairly violent path with a low volume increase till at the very end.

here's the kicker...that pump is drawing from the forward/left scavenge filter...which goes all the way to the front of the lower pan to the middle rear.

you can figure that this pump aint doing shit but spewing a nice frothy, low oil/high air content oilinto the forward portion of the side sump, where under acceleration...it must flow downward, then rearward past the pressure pump filter....get it low enough, suck foam. the horrible part is that the high oil concentration rear scavenge discharge is helping carry all the bubbles down to the filter, then rearward.

ive settled on two fixes since I don't give a shit about the decel side of the hydraulics.

we are "filling" the forward/left dry sump (lower pan) pickup screen with a skin of RTV from the forward edge to more than halfway back. the pickups will now only be able to suck from the rear middle of the lower pan. the goal is to keep it covered in oil instead of air. I feel this is possibly the biggest help overall.

the second thing is that since fuel cell foam likely wont stand up to the oil...im looking at using some Teflon cuttings/swarf to fill the side cover forward section from the upper scavenge discharge to the bottom above the filter. this should take care of the remaining bubbles inherent in a scavenge system.

this with overfilling should tackle everything quite nicely and cheaply.

my theory is sound, look at the hydraulic paths here to see what I mean

http://www.thechicagogarage.com/forum/midwest3800s/27992-4t80e-4t60-65-hd-10.html#post3198163

the larger side cover is certainly a boon, more oil down low but even it would probably see an increase in line pressure stability with the scavenge changes reducing the foaming a the outlets

edit fer pic

the thing is I wonder if having the pressure pump filter modified with a hole towards the rear instead of the front might be a good thing

ditching the filter entirely for a draw tube at the rear would be good if you put a filter on the cooler/primary lube loop. at least youd be assured of all the bearings/bushings getting the cleanest fluid

honestly for a street car I don't know if the lower sump screens being filled over would be the best for a street car which is on/off the throttle a lot. but it certainly makes sense for those of us in it for the acceleration, damn the torpedo's

at the least the oil de-aeration of the scavenge discharges and keeping fluid over the pressure sump with an overfilled wet tank, is not gonna compromise anything really.

ditching the filter entirely for a draw tube at the rear would be good if you put a filter on the cooler/primary lube loop. at least youd be assured of all the bearings/bushings getting the cleanest fluid

honestly for a street car I don't know if the lower sump screens being filled over would be the best for a street car which is on/off the throttle a lot. but it certainly makes sense for those of us in it for the acceleration, damn the torpedo's

at the least the oil de-aeration of the scavenge discharges and keeping fluid over the pressure sump with an overfilled wet tank, is not gonna compromise anything really.

So was thrown over here from different site on trans

So where are you getting axle parts? I am the proud recipient of a free 05 Grand Prix GTP with blown engine and lots of potential if its not rusted out!

After swapping the the 4T6xE out of my 98 Regal I like idea of larger trans?

So where are you getting axle parts? I am the proud recipient of a free 05 Grand Prix GTP with blown engine and lots of potential if its not rusted out!

After swapping the the 4T6xE out of my 98 Regal I like idea of larger trans?

So where are you getting axle parts? I am the proud recipient of a free 05 Grand Prix GTP with blown engine and lots of potential if its not rusted out!

After swapping the the 4T6xE out of my 98 Regal I like idea of larger trans?

There are at least 4 different factory axles that can work, varying lengths. You've gotta come up with a combination that fits best in your car. O'Reilly's lists all the lengths. I am running the same axle on both sides on my 4t80e Park Avenue, I forget if it's from a Deville or Bonneville, or what exactly.

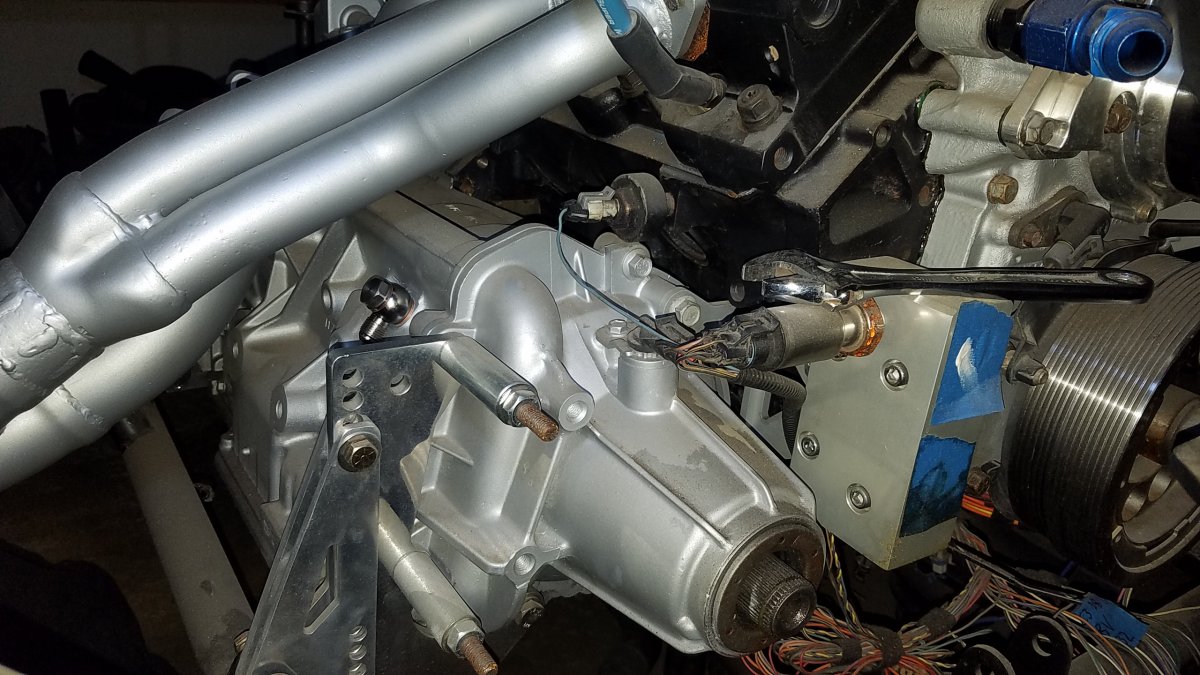

Use the 4L80E banjo fittings for header clearance. Gotta grind the nose a little shorter and stack an extra crush washer.

Clears the TOGs even.

This picture shows the pacesetters. However they have been sliced near the flange and angled upward and re-welded so they actually have more clearance than what they did initially. You can see with the factory fitting for a 3/8 Hardline isn't the best for being able to run near the header. I have been able to mangle the factory steel line and clear but I had one of them Kink during rebending and so I decided to fix it properly

All better

Clears the TOGs even.

This picture shows the pacesetters. However they have been sliced near the flange and angled upward and re-welded so they actually have more clearance than what they did initially. You can see with the factory fitting for a 3/8 Hardline isn't the best for being able to run near the header. I have been able to mangle the factory steel line and clear but I had one of them Kink during rebending and so I decided to fix it properly

All better

Probably securing it to the dry sump pan bolts

a video of the cutty as it is now and some more views of the 4t80e in its unnatural environment

Soooo I now have genuine Torsen guts to make a 4t80e Torsen diff....

Package size is almost perfect to fit the 80e diff dimensions.....

For 20$ it's a worthwhile pipe dream.

It'll sit next to the quaife 4t65e diff on the shelf and look pretty

Package size is almost perfect to fit the 80e diff dimensions.....

For 20$ it's a worthwhile pipe dream.

It'll sit next to the quaife 4t65e diff on the shelf and look pretty

Soooo I now have genuine Torsen guts to make a 4t80e Torsen diff....

Package size is almost perfect to fit the 80e diff dimensions.....

For 20$ it's a worthwhile pipe dream.

It'll sit next to the quaife 4t65e diff on the shelf and look pretty

View attachment 144866

View attachment 144867

So your gutting a 7 5/8 t/g to make a 4T80E posi? Very interested as I'm going 80E In my GXPSoooo I now have genuine Torsen guts to make a 4t80e Torsen diff....

Package size is almost perfect to fit the 80e diff dimensions.....

For 20$ it's a worthwhile pipe dream.

It'll sit next to the quaife 4t65e diff on the shelf and look pretty

View attachment 144866

View attachment 144867

I have mistaken which of my transaxles was the early and late model production 4t80e.

I have corrected my posts below.

For posterity...

All oe 65e inners I've seen were barrel faced rollers. Small dia rollers.

[LATE MODEL 01] tulip and tripod. Large dia flat rollers.

Shallow narrow indents in od of tulip.

I'm guessing there might have been a cost savings difference or just running production changes?

This is the [EARLY MODEL] Small diameter flat side rollers. Large indents reminiscent of the 65e tulips.

This is a GM reman 95 80e

I have corrected my posts below.

For posterity...

All oe 65e inners I've seen were barrel faced rollers. Small dia rollers.

[LATE MODEL 01] tulip and tripod. Large dia flat rollers.

Shallow narrow indents in od of tulip.

I'm guessing there might have been a cost savings difference or just running production changes?

This is the [EARLY MODEL] Small diameter flat side rollers. Large indents reminiscent of the 65e tulips.

This is a GM reman 95 80e

4t80e "g body" mount cody is test fitting.

Thread Info

-

365Replies

-

33KViews

-

Participants list