Install the TCG app

how_to_install_app_on_ios

follow_along_with_video_below_to_see_how_to_install_our_site_as_web_app

Note: this_feature_currently_requires_accessing_site_using_safari

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

💬 OT 3D printers...who has one?

- Thread starter Lord Tin Foilhat

- Start date

More options

Who Replied?you could always print in side bolt holes and make a couple steel rings, cut em in half, drill em and reinforce the chassis.

three's tons of printed things with bolted on Homedepot steel sheet/angle/strut to add strength.

reinforcing is way easier than fabing the whole bugger., hell you could weld on a couple bolts to put a couple angles below the ways to let you clamp the steel side plates down or at least be a safety feature if the plastic ever tries to lift/break with the upward force.

three's tons of printed things with bolted on Homedepot steel sheet/angle/strut to add strength.

reinforcing is way easier than fabing the whole bugger., hell you could weld on a couple bolts to put a couple angles below the ways to let you clamp the steel side plates down or at least be a safety feature if the plastic ever tries to lift/break with the upward force.

Just wanted to say be careful trying to do temperature calibrations via CLI. I found out that my basic bitch printer will go up to at least 460C in a few moments even with just a standard shitty end heater. Oops

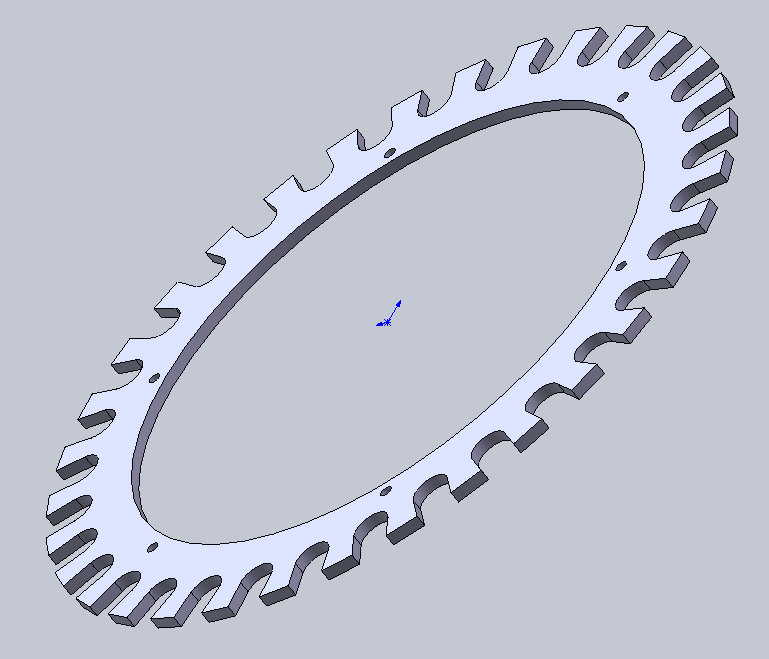

Drew this up and have it printing now. The goal is to take a 2.5 gallon bucket (I think a 2 gallon bucket is the same diameter, just shorter) put this in the bottom and see if I can make it into a brass feeder. I have seen a few other plans but they have you print the body off and I decided that was sort of silly so I'm going to design my own. I'm obviously not going to keep the bucket this tall but will cut it down. This is more of a proof of concept to see how it works out. The way a typical case feeder works is that the cases get caught in the notches and as they go up the base will weigh them down keeping them in however if the case is base up the weight will cause it to fall back out of the notch. I may need some refinements of the notch its self though so we'll see. I still need to make a center hub, bracketry and figure out a motor drive. The goal is to make em to feed my Lee APP, my Dillon 550 and my Hornady progressive press.

Something I didn't know about buckets is they have a significant amount of taper from the top to the bottom. Something like an inch basically. I guess I shouldn't be surprised but they sure don't look that way. I took my measurement off the bottom and we'll see how close the first print is.

Something I didn't know about buckets is they have a significant amount of taper from the top to the bottom. Something like an inch basically. I guess I shouldn't be surprised but they sure don't look that way. I took my measurement off the bottom and we'll see how close the first print is.

Well im getting there....slowly

I still haven't enabled stealth Chopper I still have to finish the new brackets for the x axis Optical end limit switches.

Right now it's functioning on a mechanical switch but Optical is the only solution for perfect synchronizing of the two high-torque steppers.

The y-axis is working out fantastically except I need to rework the belt tensioning design it's too much of a pain I need to make it so I just turn a screw and it tightens up.

I'm still having some fun with the z homing.

I still haven't enabled stealth Chopper I still have to finish the new brackets for the x axis Optical end limit switches.

Right now it's functioning on a mechanical switch but Optical is the only solution for perfect synchronizing of the two high-torque steppers.

The y-axis is working out fantastically except I need to rework the belt tensioning design it's too much of a pain I need to make it so I just turn a screw and it tightens up.

I'm still having some fun with the z homing.

get rid of retracts with that stuff, i had the same thing, gets really bad with the yellow /gold color of the ttyt3d.

it cooks insid ethe hotend and the retracts especially multiple retracts cause it to stir crap up near the heatbrake and clog the chamber nozzle

the best soltuion was the removal of retracts and selecting hiding the Z seam in cura.

print test towers till you get it close (upside down table/row of towers tests you can DL off of thingiverse)

it cooks insid ethe hotend and the retracts especially multiple retracts cause it to stir crap up near the heatbrake and clog the chamber nozzle

the best soltuion was the removal of retracts and selecting hiding the Z seam in cura.

print test towers till you get it close (upside down table/row of towers tests you can DL off of thingiverse)

get rid of retracts with that stuff, i had the same thing, gets really bad with the yellow /gold color of the ttyt3d.

it cooks insid ethe hotend and the retracts especially multiple retracts cause it to stir crap up near the heatbrake and clog the chamber nozzle

the best soltuion was the removal of retracts and selecting hiding the Z seam in cura.

print test towers till you get it close (upside down table/row of towers tests you can DL off of thingiverse)

The esun PLA+ wouldn't do this as well by any chance would it?

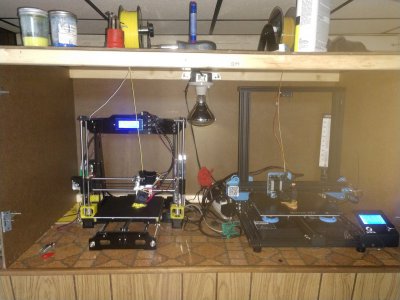

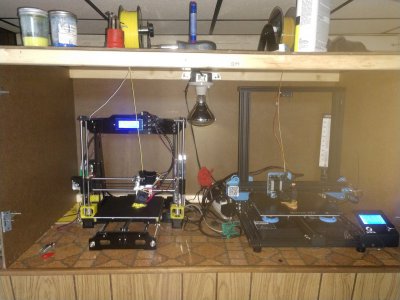

Had to wrench on both of these today, the Sovol had a major clog that took me heating up and melting plastic out of the nozzle (I think that putting it on the ABS Pre-heat melted up the nozzle) and re-did the liner in the nozzle. I also finished rebuilding the Tronxy which consisted of re-soldering the temperature sensor wire, re-mounting the belt and general re-assembly of the printer. I'm just throwing some PLA around right now, I tried to do ABS on the Tronxy and didn't get good adhesion.

My enclosure needs another set of hinges, I bought some and they're just too small. I'll have to either print something or go buy it. Don't care which at this point just need a fully functioning door on both sides. This is just PLA but with ABS I will need the heat.

My enclosure needs another set of hinges, I bought some and they're just too small. I'll have to either print something or go buy it. Don't care which at this point just need a fully functioning door on both sides. This is just PLA but with ABS I will need the heat.

Ran it on the tronxy which has a non all metal hot end. I had read that there were signs of heat creep. guess that is true, going to have to play around some with my setup I guess. I may end up looking for a better hot end too, the knockoff has served me pretty well with abs but I think it may be holding my quality back. Theoretically I could stick the original back on with Capricorn high heat Tubing and be gtg for abs too.

Looks good. I need to turn mine on and do a few prints this week

The skr board was hands down the best purchase. Dont go with the creality silent board.I think I need to finally get my printer quiet.

Bit of a install, but so worth it.

You got the full screen too right?The skr board was hands down the best purchase. Dont go with the creality silent board.

Bit of a install, but so worth it.

Adding bracing and just adding Mass to the printer is a huge help if you can get some extra drop nuts and bolts to secure your printer to the bench that would be even better.

I've been working on and water jetting brackets to reinforce my Nereus gantry.

All your moving Parts should be as light as possible and the Machine should be as rigid as possible.

I've also been working on extra brackets that would let me build an enclosure using the T slot Extrusion

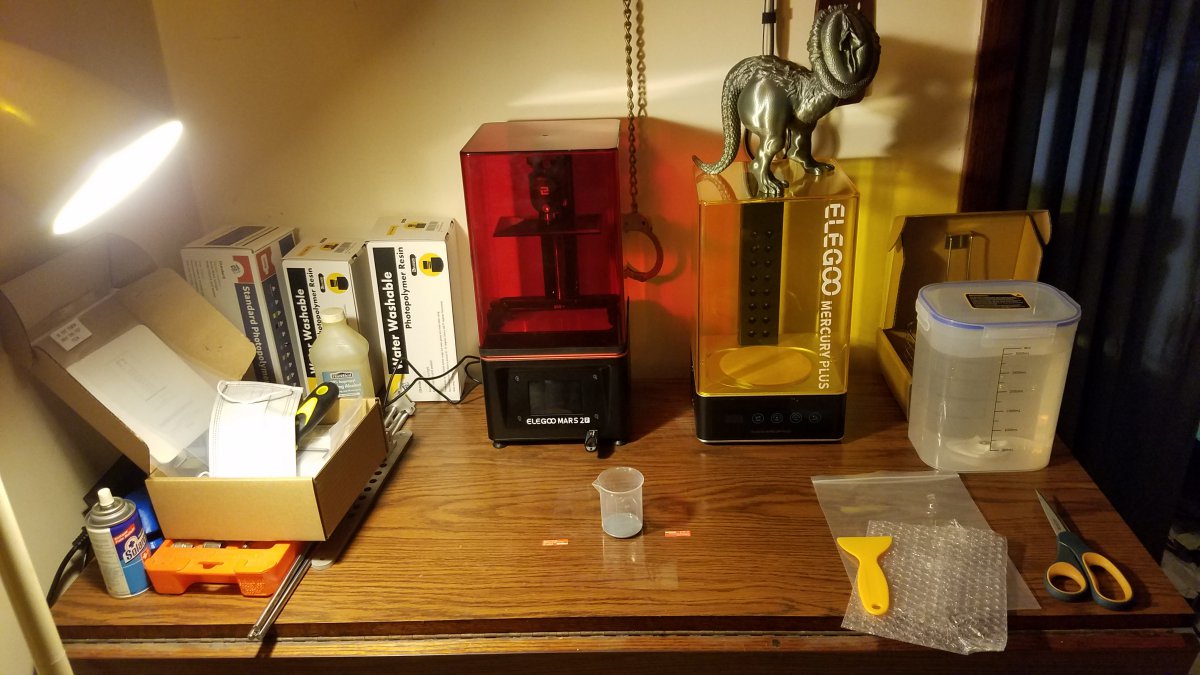

We also picked up this little assortment fer the smaller figurines and Dungeons & Dragons type s***.

I've been working on and water jetting brackets to reinforce my Nereus gantry.

All your moving Parts should be as light as possible and the Machine should be as rigid as possible.

I've also been working on extra brackets that would let me build an enclosure using the T slot Extrusion

We also picked up this little assortment fer the smaller figurines and Dungeons & Dragons type s***.

And don't forget to do a cold Pull Guys....

Yeah it's annoying but now I do it pretty much anytime I know the printers doing something with a decent amount of print time and retractions.

All I know is that half the time when I don't do it is the half of the time when I wish I did

Yeah it's annoying but now I do it pretty much anytime I know the printers doing something with a decent amount of print time and retractions.

All I know is that half the time when I don't do it is the half of the time when I wish I did

Yup but honestly the screen isnt needed and had half ass support in marlin...at least 6 months ago it did, i havent checked recently.

Basically i would use the touch screen interface for filament changes and that's it. It is a lot easier to set temperature and feed in touch screen mode... But it severely lacks any sort of useful info when printing. It just displays bed and nozzle temp...thats it.

So during printing or when not changing filament, the screen is always on marlin mode. In marlin mode it is like the old screen and displays all the print info during print (status, line count, temp, etc..) Just no touch.

Did you try foam blocks under a concrete block yet? Seems like a cheap investment before doing a board.

Not sure that does anything for the ender stepper driver noise. It’s not the actual printing that’s loud.

Best enclosure is printer enclosure from the start...... a circa 2003 dot matrix printer.... Printronix PSA p5205b gutted.

It sound dampened and has an external power switch a high-quality one at that.... front and rear mag sealed doors and mag sealed lid for sound/air tight operation.... once the air cooling holes are blocked off

For the Tevo Nereus? ....but likely it'll be our heated/dried fillament cabinet....lots of cf abs is gonna be used for the 442 parts.... this with a mosaic allowing filament splicing would let us run multiple days and roll after roll prints, without interruption.

It sound dampened and has an external power switch a high-quality one at that.... front and rear mag sealed doors and mag sealed lid for sound/air tight operation.... once the air cooling holes are blocked off

For the Tevo Nereus? ....but likely it'll be our heated/dried fillament cabinet....lots of cf abs is gonna be used for the 442 parts.... this with a mosaic allowing filament splicing would let us run multiple days and roll after roll prints, without interruption.

Sweet.Best enclosure is printer enclosure from the start...... a circa 2003 dot matrix printer.... Printronix PSA p5205b gutted.

It sound dampened and has an external power switch a high-quality one at that.... front and rear mag sealed doors and mag sealed lid for sound/air tight operation.... once the air cooling holes are blocked off

For the Tevo Nereus? ....but likely it'll be our heated/dried fillament cabinet

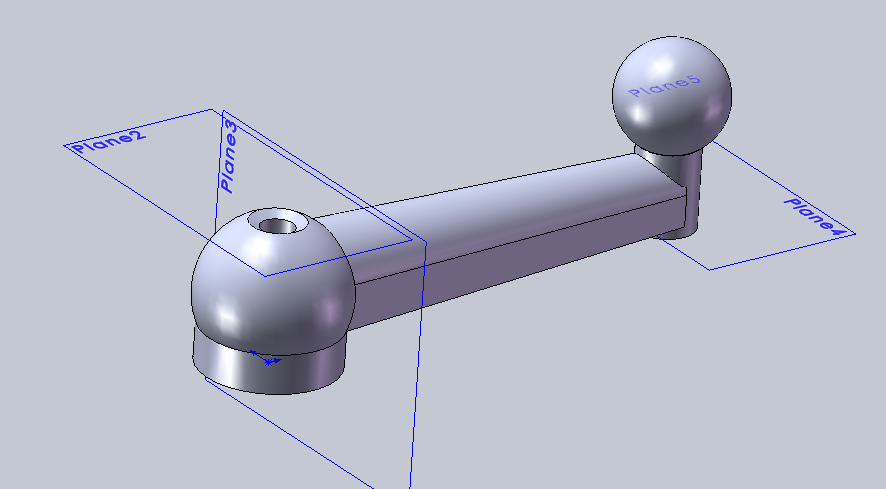

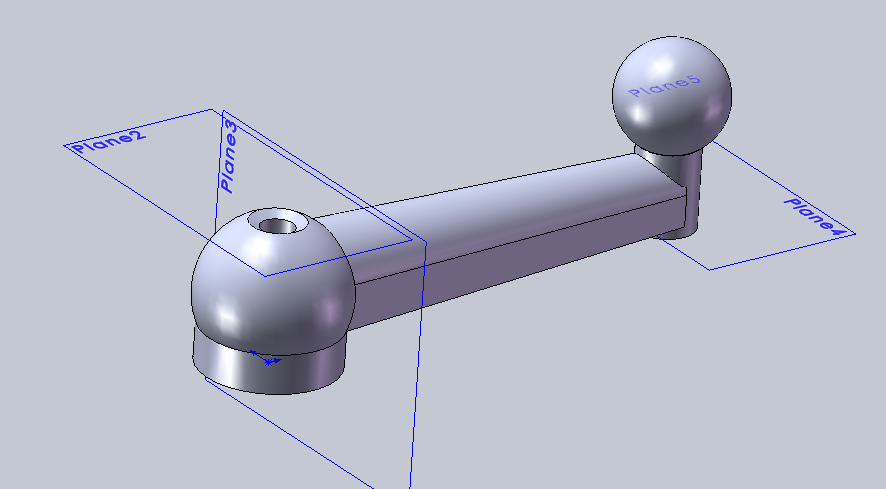

View attachment 86661

I'm wanting to get my lathe going again, I need to get some belts for it and a few of my handles are broken. This is the splut nut handle, I need to make one for the compound still but am not quite there yet. If it works out well I may print a few out and ebay em.

ED:Those printers were fuckin beasts man. Artifacts of a bygone era indeed.

ED:Those printers were fuckin beasts man. Artifacts of a bygone era indeed.

"PRINT THE PLANET!!!" /Hackers reference

Im still in awe of yer steadyrest.

We've sort of decided since we now have three large printers with the Jaws 5 and 4 being slightly smaller than the Jaws 6.... we figure we definitely need a place to store and keep filament while also supplying 3 machines.

So we're definitely turning the cabinet into a heated/dried spool holder that will allow us to put up to 4, 10kg spools in the top hatch cover area and 10+, 1 kg spools in the lower area.

So anyways on to the good news I finally have 98% of the rrf 3.2.2 firmware sorted out.... and I even ran the g32 bed compensation.

I took a video showing her off and running it through its paces.

I figured you guys wood enjoy this...

Im still in awe of yer steadyrest.

We've sort of decided since we now have three large printers with the Jaws 5 and 4 being slightly smaller than the Jaws 6.... we figure we definitely need a place to store and keep filament while also supplying 3 machines.

So we're definitely turning the cabinet into a heated/dried spool holder that will allow us to put up to 4, 10kg spools in the top hatch cover area and 10+, 1 kg spools in the lower area.

So anyways on to the good news I finally have 98% of the rrf 3.2.2 firmware sorted out.... and I even ran the g32 bed compensation.

I took a video showing her off and running it through its paces.

I figured you guys wood enjoy this...

Thread Info

-

1KReplies

-

26KViews

-

Participants list