I've actually read that very post from Rod in the past.

Also have seen that chart passed around as a possibly close representation of the PT88... but then I've heard ppl say the PT88 is capable of 132lbs/min too.

In any case, really all the reassurance that I need to have is that I've heard multiple reputable folks tell me that this turbo will be capable of 1000WHP+ which is sort of where I'm pretty sure I know I'll be content. Therefore, seems to me that the PT88 will suffice just fine without spending the extra money to get to a T6 turbo.

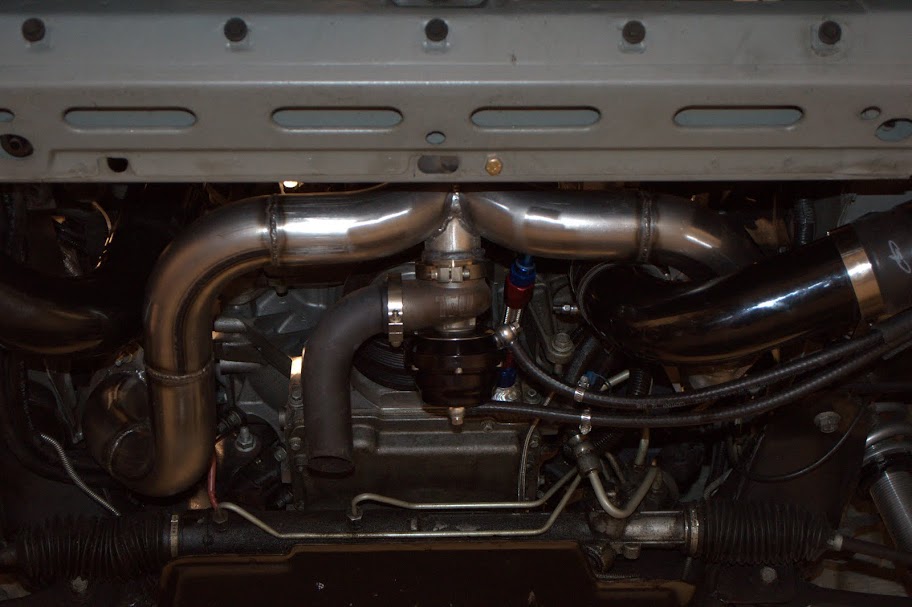

I just want it done at this point. The weather is getting nice outside and my car is without piping or a turbo... I just want all the parts to arrive so I can send the car over to Marty and get the piping done so it can go to Brandon so I can get busy trying to tear the rubber off the wheels.

Also have seen that chart passed around as a possibly close representation of the PT88... but then I've heard ppl say the PT88 is capable of 132lbs/min too.

In any case, really all the reassurance that I need to have is that I've heard multiple reputable folks tell me that this turbo will be capable of 1000WHP+ which is sort of where I'm pretty sure I know I'll be content. Therefore, seems to me that the PT88 will suffice just fine without spending the extra money to get to a T6 turbo.

I just want it done at this point. The weather is getting nice outside and my car is without piping or a turbo... I just want all the parts to arrive so I can send the car over to Marty and get the piping done so it can go to Brandon so I can get busy trying to tear the rubber off the wheels.

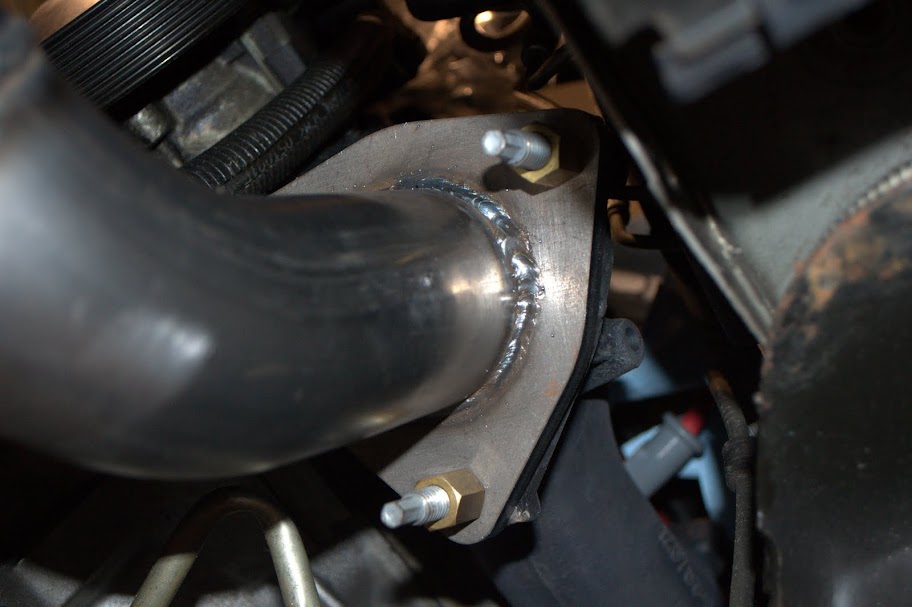

This is the piece that was hole sawed out for the WG.

This is the piece that was hole sawed out for the WG.