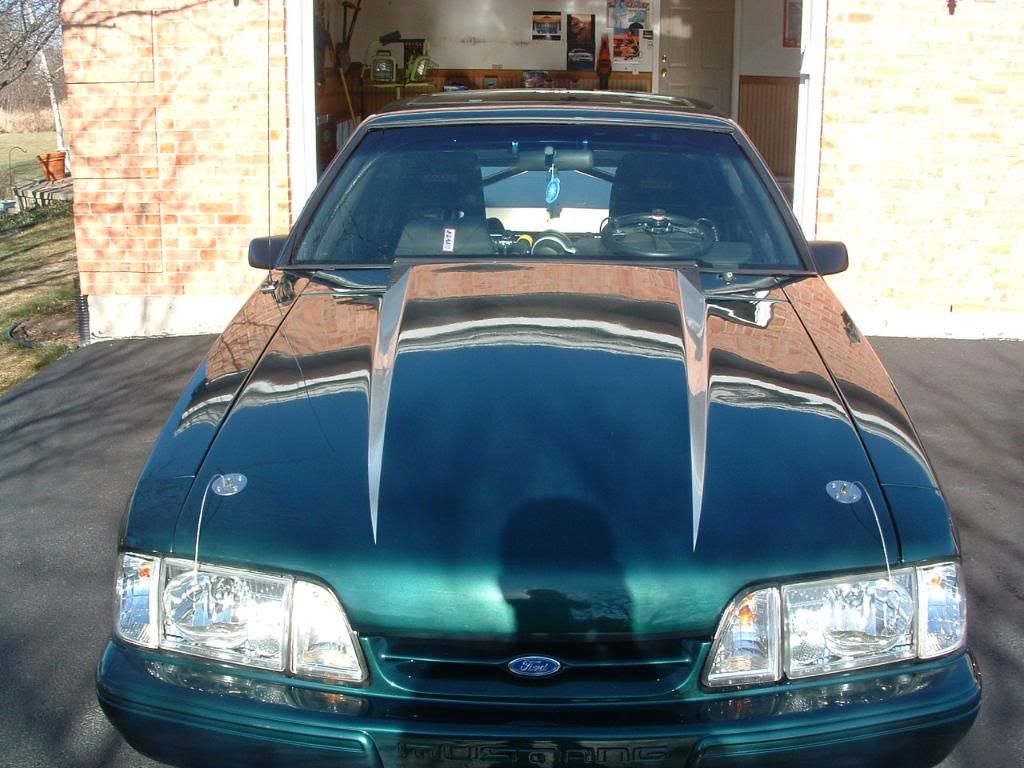

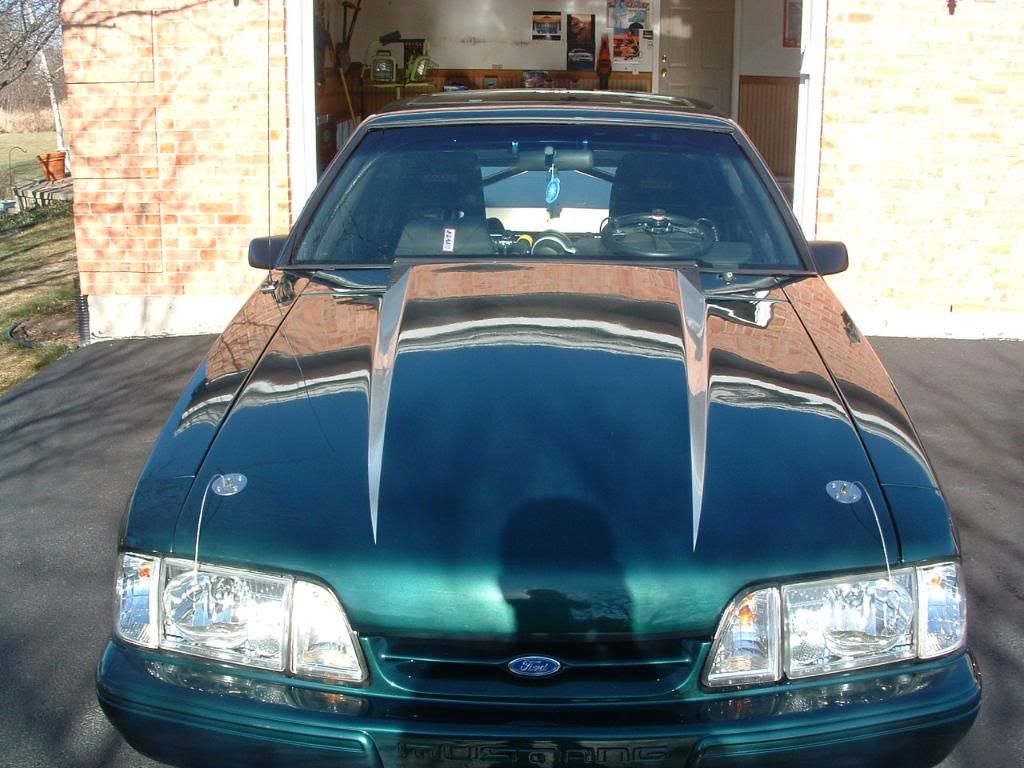

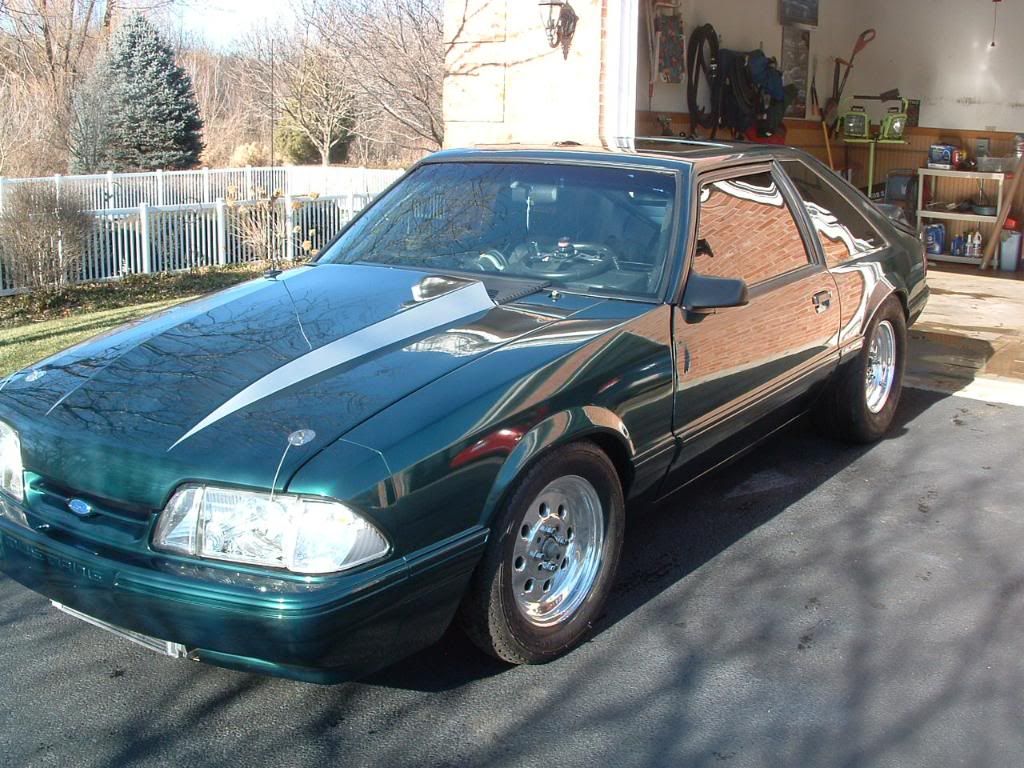

after 4 years, countless head aches, and who knows how much money.... here she is guys

This project has so much time and effort i dont think i will ever sell the car. Everything (except the rearend), was assembled and doen in my garage, mainly by myself with a few key friends and dad for moral support! great learning experiance for me.

Its a 4.6 2004 cobra engine, run off of a ron francis "detail zone" wiring harness. Body harnes is all seperate.

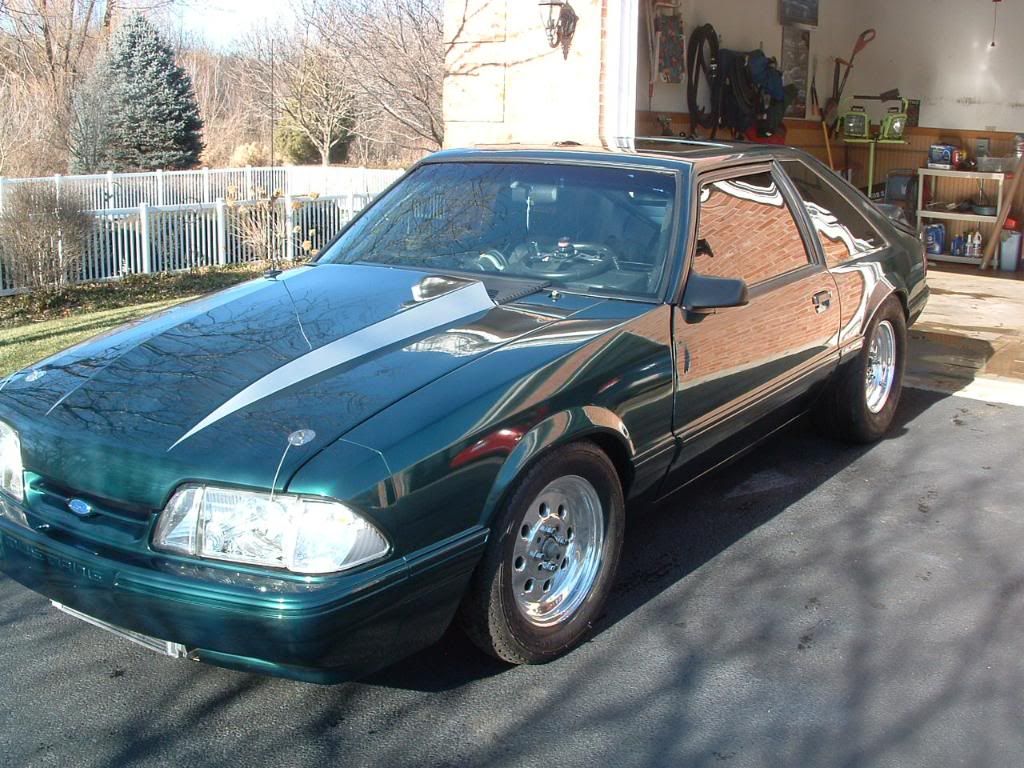

Car has a TH400 built in Indiana, reverse manual valve body with trans brake, and an un known converter (still trying to get a hold of the guy who made it)

Rear end has 31 spline axles with 3.55 gears a spool, c clip elimin.

Suspension is mainly Team z and Strange, with coil overs in all 4 corners

Fluidine provided all the coiling tanks and radiator/heat exchanger.

fuil system is a glenns high performance twin 255 walbro kit rated at 1000hp with the sumpt tank.

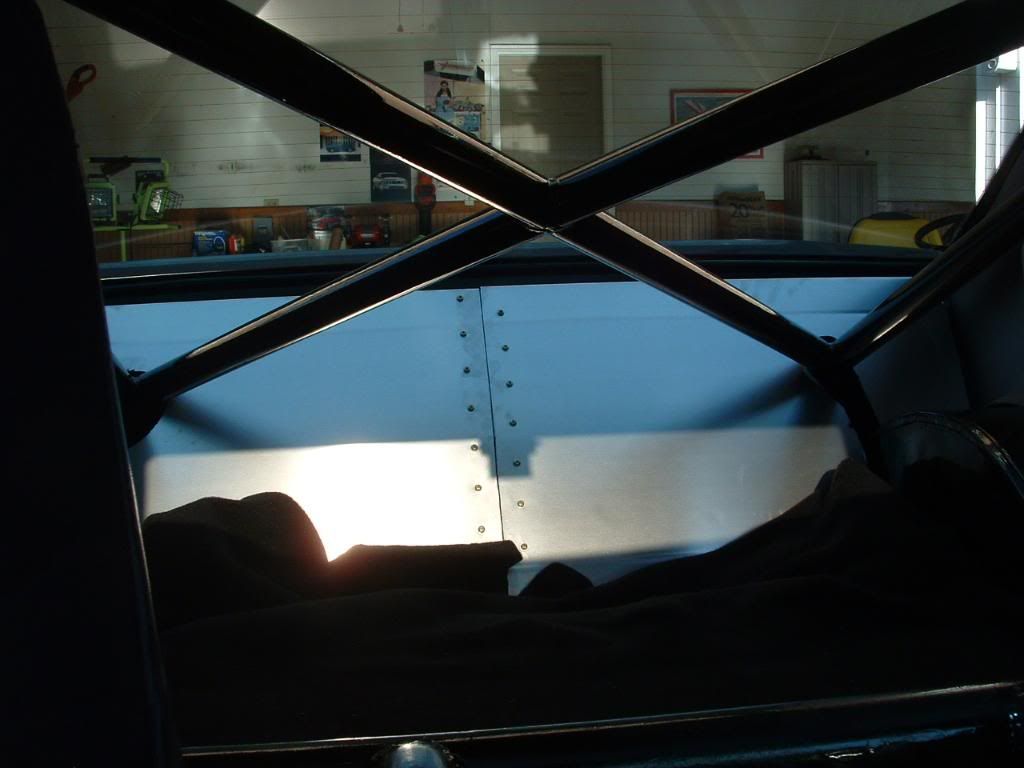

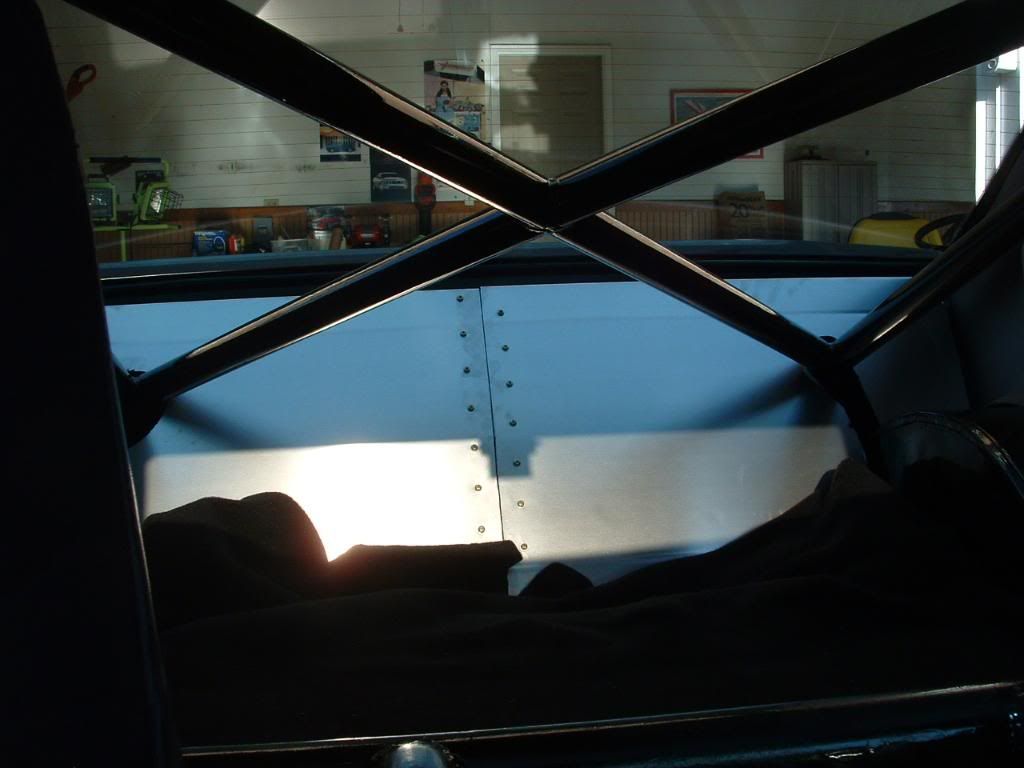

Interior is all custom starting with a wolf craft 10 point chromoly cage that had the kirkey seat brackets added to it. The back half was cut out for the instalation of the mini tubs (after cage was in) and a bulk head (which i cut and modified to fit around the new back bars that i cut/nothced myself.

my buddies z and my car

burn out time

This project has so much time and effort i dont think i will ever sell the car. Everything (except the rearend), was assembled and doen in my garage, mainly by myself with a few key friends and dad for moral support! great learning experiance for me.

Its a 4.6 2004 cobra engine, run off of a ron francis "detail zone" wiring harness. Body harnes is all seperate.

Car has a TH400 built in Indiana, reverse manual valve body with trans brake, and an un known converter (still trying to get a hold of the guy who made it)

Rear end has 31 spline axles with 3.55 gears a spool, c clip elimin.

Suspension is mainly Team z and Strange, with coil overs in all 4 corners

Fluidine provided all the coiling tanks and radiator/heat exchanger.

fuil system is a glenns high performance twin 255 walbro kit rated at 1000hp with the sumpt tank.

Interior is all custom starting with a wolf craft 10 point chromoly cage that had the kirkey seat brackets added to it. The back half was cut out for the instalation of the mini tubs (after cage was in) and a bulk head (which i cut and modified to fit around the new back bars that i cut/nothced myself.

my buddies z and my car

burn out time