I'll try and keep this thread updated as the NAGTROC gets updated.

GT1R Shop GTR Rebuild, shooting for the moon! - R35 GT-R - GT-R Life

GT1R Shop GTR Rebuild, shooting for the moon! - R35 GT-R - GT-R Life

We've been a little quiet and a lot busy here at the shop. Finally have things coming together enough to share. I'll keep this thread updated with progress pictures between now and TX2K, which the goal is to be finished for. We will have lots of new things and no testing time, so I don't expect to set the world on fire at TX2K, but I do expect to make some noise for 2015.addleshift:

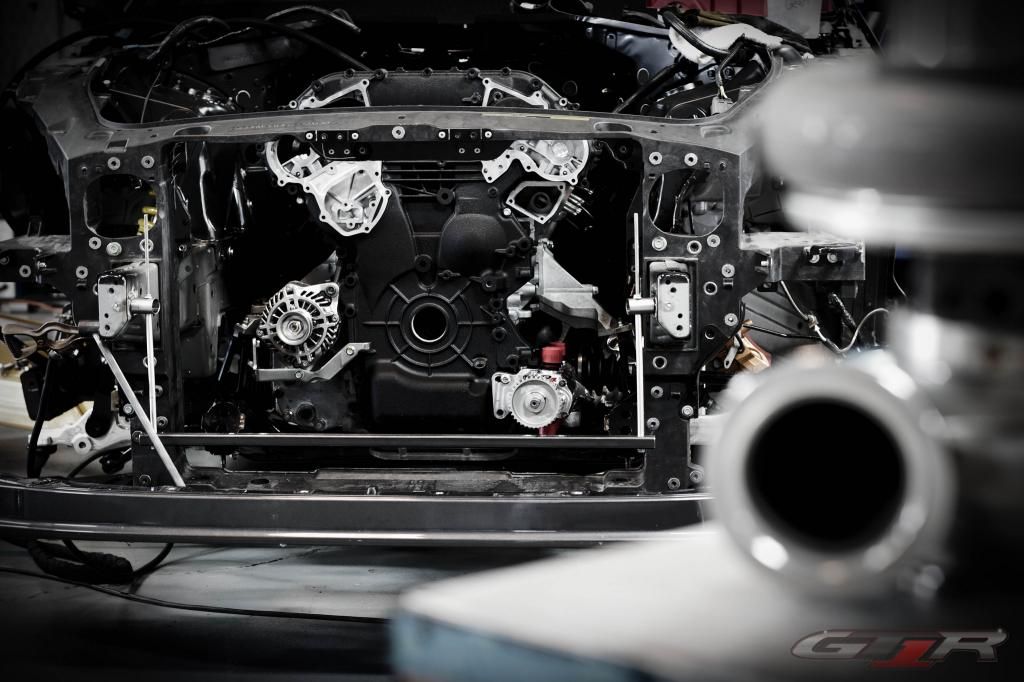

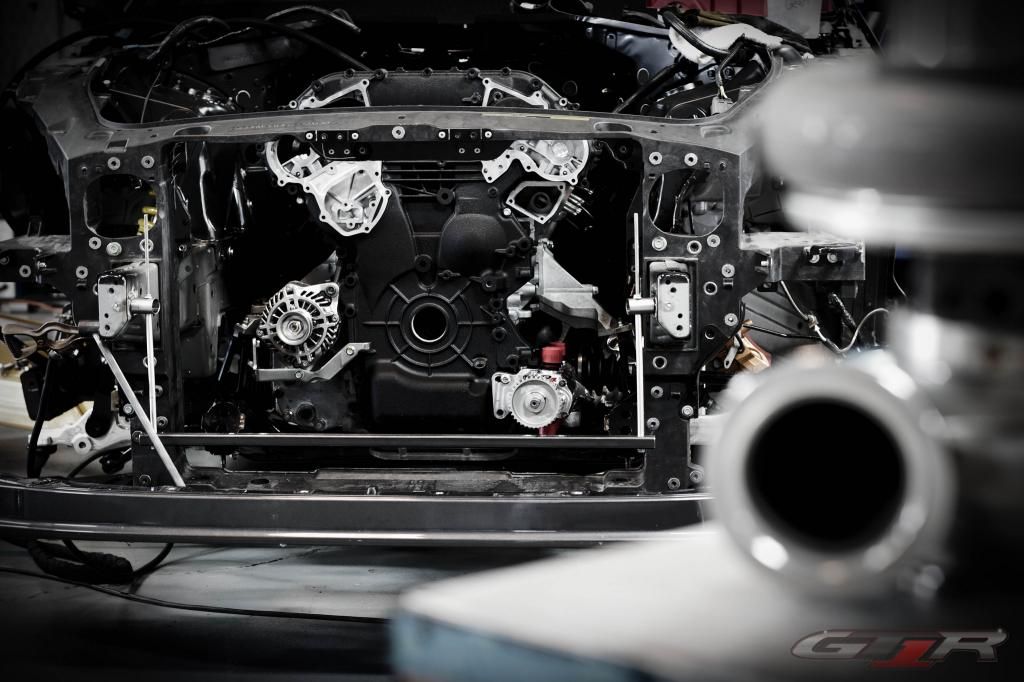

The build is based around our GT1R 4 liter engine with some additional block stiffening that we hope will hold us over until our billet block is ready.

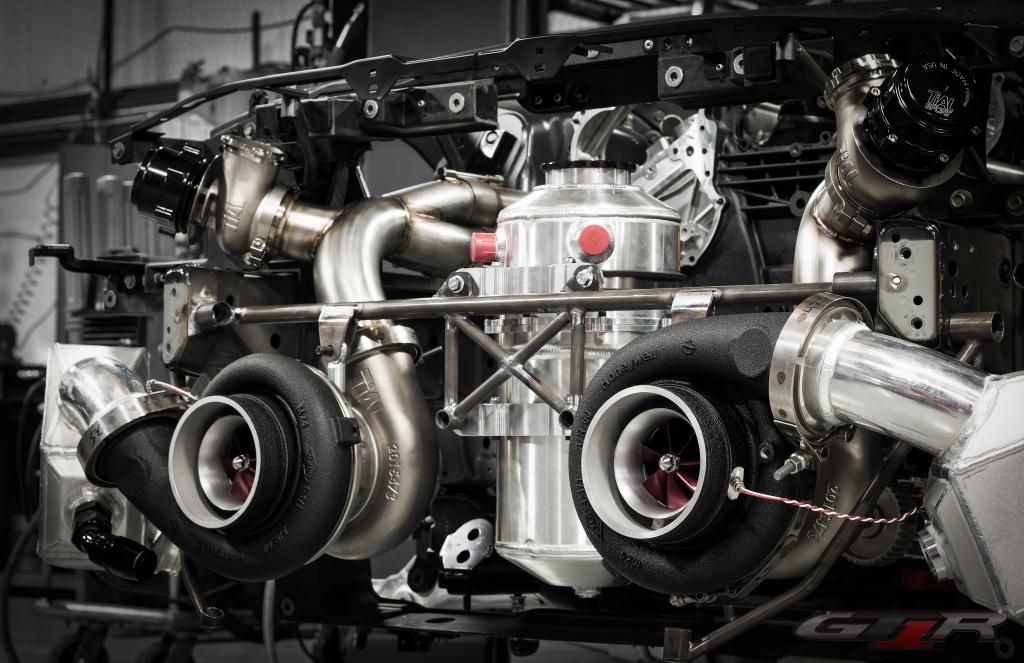

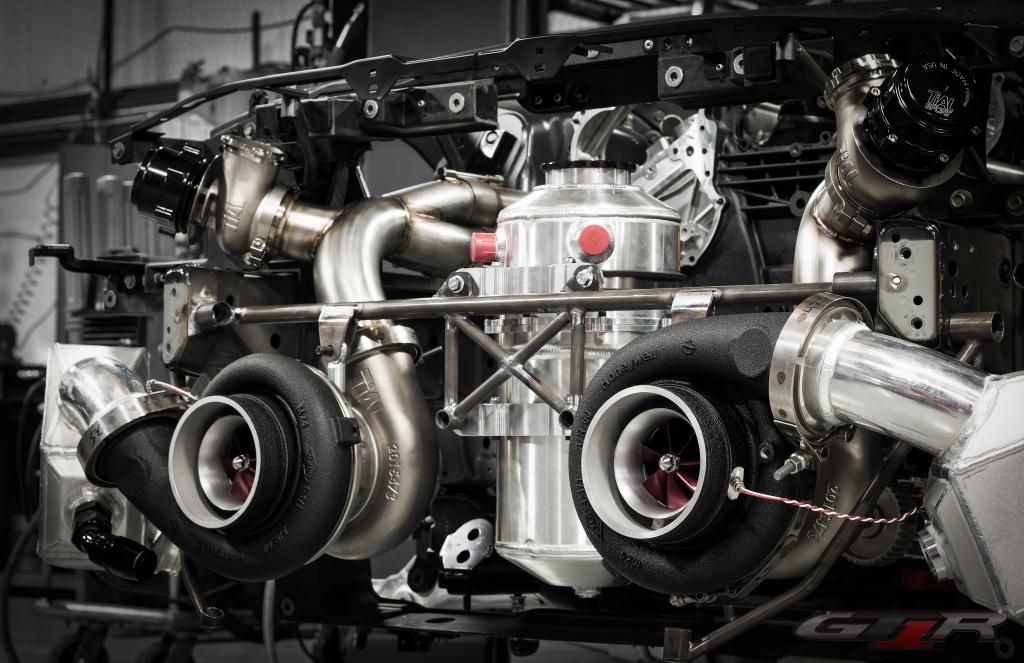

The turbos are from Forced Performance, they are HTZ4505's with a couple special touches. As you can see in the pics we will have turbo shaft speed monitored along with exhaust backpressure and in the near future wastegate position on the TiAL 60mm wastegates. We'll have a very good idea of what's going on and why, and where improvements can be made. These turbos are good for a comfortable 1200+hp a piece, so running the car around 2000hp will have the system in a very comfortable area with plenty of room to go as engine development catches up.

The intercoolers are built in house using Garrett air/water cores.

The headers are built in house using 321 16 gauge stainless tubing and Burns Stainless double slip fit collectors. The downpipes and dumptubes will both come up through the hood for TX2K and the exhaust will run back under the car for Texas Invitational. We've got an AMS carbon hood (beautiful piece) for the drag stuff with the downpipes coming through it and will use the stock hood for other events where we have to run an exhaust system.

The dry sump oiling system is a kit that Magnus Motorsports has been working on and will be available for the public very soon. There are many advantages to a proper dry sump system and at this level it's almost a necessity.

Race Spec is building a nice mil spec engine harness for the car, will have a firewall disconnect in the center of the firewall and then all tefzel wire and Raychem shrink and boots from there out.

Anyways, a few pics for now and i'll keep info and pics coming as things progress.