Boomba Racing would like to take all of our forum members on a tour of our shop located at 635 Wood Dale, IL.

Anybody who has been following us knows we have moved to a new larger facility.

Everything you see in this post is all under one roof, meaning if you would stop on by in person you would get this same exact tour.

We would like to take a moment of your time and go into more depth of exactly how we go about our cutting edge design process.

For this example we will be looking at our throttle body line, rest assured that you can expect the same attention to detail from all of our products.

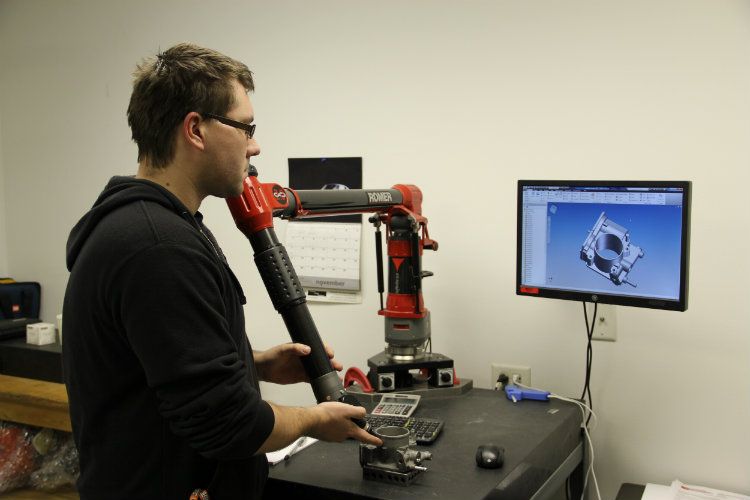

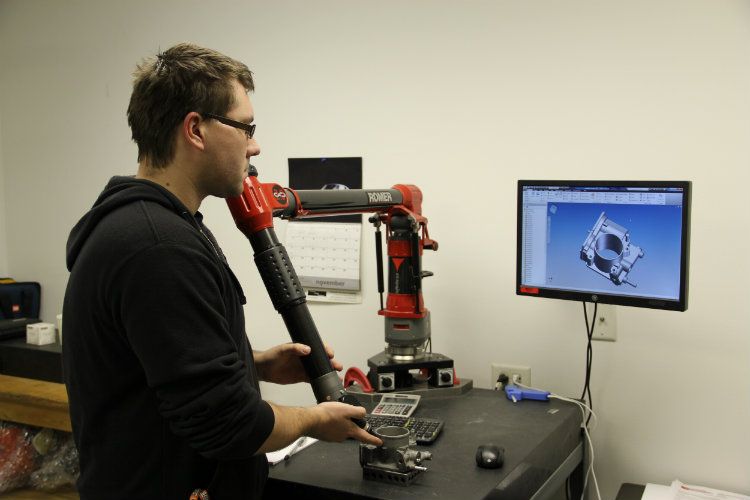

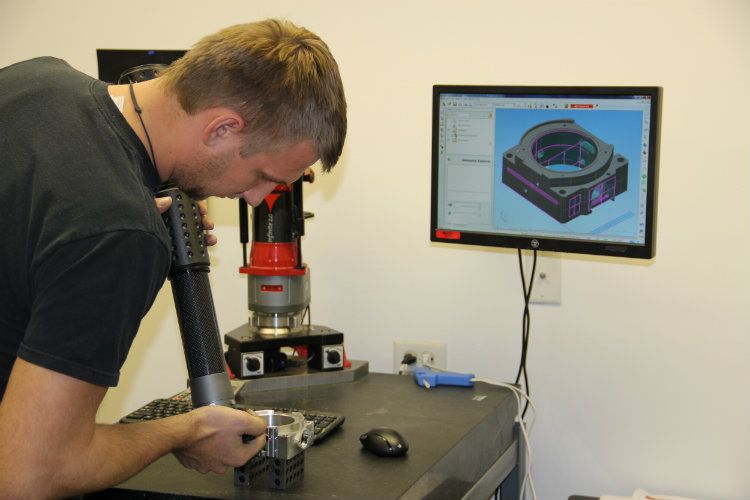

1. Once we conceptualize what product to manufacture, we first start off by reverse engineering the OEM product.

In order to do this we use our ROMER INFINITE 2.0 which is a portable Coordinate-Measuring Machine (CMM).

It is not uncommon for us to use our CMM to not only obtain mounting locations, but also engine bay clearances.

Often times the intake manifold as well as any other obstructions will be modeled.

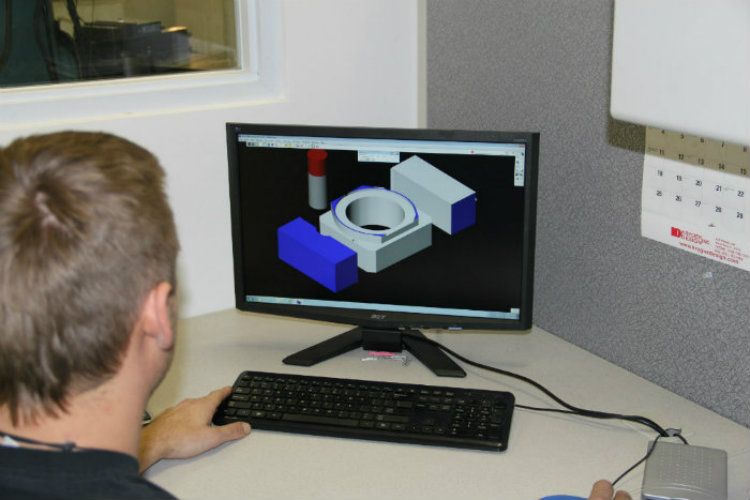

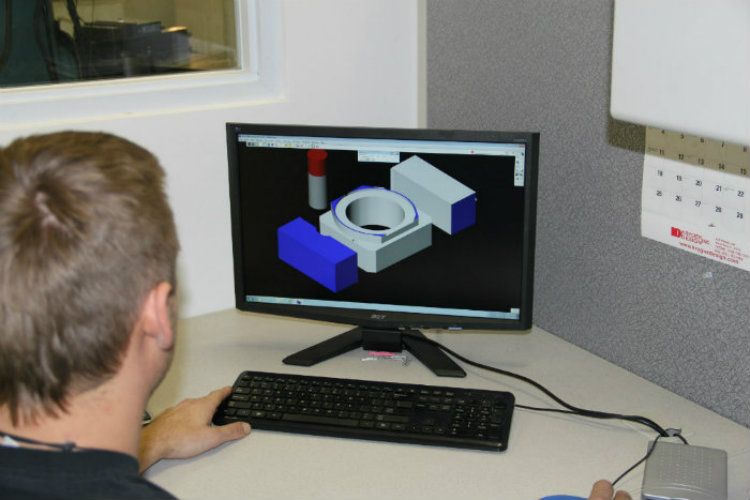

2. This is a Boomba Racing Engineer’s natural habitat.

Their diet relies heavily on Red Bull and if they perform well they are rewarded with Oreos.

They do not like to be touched.

3. Boomba Racing uses Autodesk Inventor for all 3D Modeling.

SolidWorks may be the industry norm because it is cheaper and much easier to use, but it lacks all the features we need for our products.

We are not just simply a race shop, we also design and manufacture custom automation solutions.

I really wish I could share some of those projects, but non-disclosure agreements will not allow me to.

4. After a 3D model is designed, our certified programmers can upload it into GibbsCam to begin programming for the manufacturing runs.

Again, Mastercam is also the industry norm, but we found GibbsCam to be much faster.

Machining costs are astronomical, so any time we save in this department transitions to lower pricing for the end user.

5. Behind Boomba Racing’s doors you will find a plethora of Haas Computer Numerical Control (CNC) Mills and Lathe as well as Fanuc Wire EDMs.

No machine shop is complete without manual mills, lathes, and grinders.

6. Can't forget all of our welders.

7. Boomba Racing assembles every one of our products in house; it is the only way we can ensure our strict quality standards are upheld.

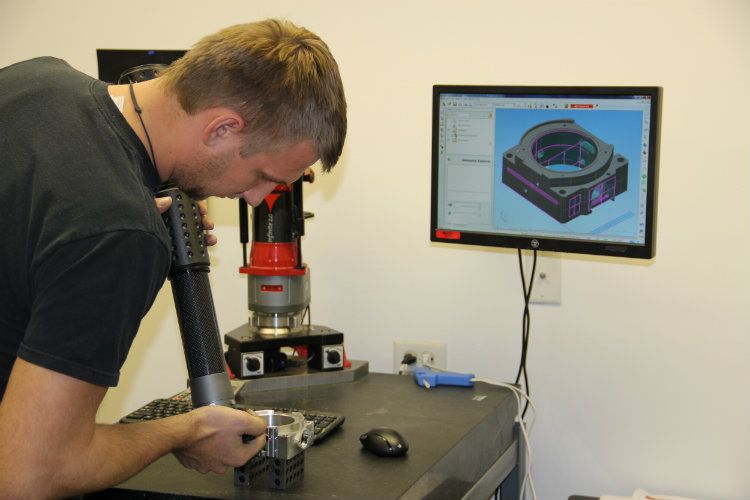

8. Before the product even sees the car, everything is carefully calibrated and measured.

We even have a devoted test bench.

Our Romer doubles as a handy piece of technological measuring device for our production runs.

To ensure everything is to the upmost standard we go as far as design and build our own fixtures for testing and assembly.

I will touch base on our pressure tester in a later issue.

9. We like to keep a clean work place, our service area is no different.

Between all of our machinists and masterful technicians, you can find any tool you would ever need under our roof.

Everything also has its place.

Also a sneak peak of our project car, currently being torn down.

------>link<------

10. Of course we take real data and do back to back comparisons on our AWD Mustang Dynamometer.

We prefer the Mustang as it applies the most realistic load a car would experience out on the street.

Watch us build it

11. At this point you are probably thinking that the product is ready to sell, well I hate to break it to you but you are wrong.

A small beta testing group is selected and the product is then tested in the real world.

If there are any flaws we will start the process all over again from scratch.

Boomba Racing will never sell a product to the market unless we fully stand behind it and we feel it is of the highest quality and performance.

12. Only after all of these conditions are met, a product has the right to sit in our warehouse on our shelves.

As you can see, we keep a healthy inventory to keep up with all of our clients’ demands.

We even plot our own stickers.

13. Our friendly and knowledgeable staff is always sitting by anxiously waiting to answer any questions or place any orders.

They are also very handsome.

Especially the one in glasses.

At least that is what my mother tells me.

So come pay us a visit; after all, seeing is believing.

Anybody who has been following us knows we have moved to a new larger facility.

Everything you see in this post is all under one roof, meaning if you would stop on by in person you would get this same exact tour.

We would like to take a moment of your time and go into more depth of exactly how we go about our cutting edge design process.

For this example we will be looking at our throttle body line, rest assured that you can expect the same attention to detail from all of our products.

1. Once we conceptualize what product to manufacture, we first start off by reverse engineering the OEM product.

In order to do this we use our ROMER INFINITE 2.0 which is a portable Coordinate-Measuring Machine (CMM).

It is not uncommon for us to use our CMM to not only obtain mounting locations, but also engine bay clearances.

Often times the intake manifold as well as any other obstructions will be modeled.

2. This is a Boomba Racing Engineer’s natural habitat.

Their diet relies heavily on Red Bull and if they perform well they are rewarded with Oreos.

They do not like to be touched.

3. Boomba Racing uses Autodesk Inventor for all 3D Modeling.

SolidWorks may be the industry norm because it is cheaper and much easier to use, but it lacks all the features we need for our products.

We are not just simply a race shop, we also design and manufacture custom automation solutions.

I really wish I could share some of those projects, but non-disclosure agreements will not allow me to.

4. After a 3D model is designed, our certified programmers can upload it into GibbsCam to begin programming for the manufacturing runs.

Again, Mastercam is also the industry norm, but we found GibbsCam to be much faster.

Machining costs are astronomical, so any time we save in this department transitions to lower pricing for the end user.

5. Behind Boomba Racing’s doors you will find a plethora of Haas Computer Numerical Control (CNC) Mills and Lathe as well as Fanuc Wire EDMs.

No machine shop is complete without manual mills, lathes, and grinders.

6. Can't forget all of our welders.

7. Boomba Racing assembles every one of our products in house; it is the only way we can ensure our strict quality standards are upheld.

8. Before the product even sees the car, everything is carefully calibrated and measured.

We even have a devoted test bench.

Our Romer doubles as a handy piece of technological measuring device for our production runs.

To ensure everything is to the upmost standard we go as far as design and build our own fixtures for testing and assembly.

I will touch base on our pressure tester in a later issue.

9. We like to keep a clean work place, our service area is no different.

Between all of our machinists and masterful technicians, you can find any tool you would ever need under our roof.

Everything also has its place.

Also a sneak peak of our project car, currently being torn down.

------>link<------

10. Of course we take real data and do back to back comparisons on our AWD Mustang Dynamometer.

We prefer the Mustang as it applies the most realistic load a car would experience out on the street.

Watch us build it

11. At this point you are probably thinking that the product is ready to sell, well I hate to break it to you but you are wrong.

A small beta testing group is selected and the product is then tested in the real world.

If there are any flaws we will start the process all over again from scratch.

Boomba Racing will never sell a product to the market unless we fully stand behind it and we feel it is of the highest quality and performance.

12. Only after all of these conditions are met, a product has the right to sit in our warehouse on our shelves.

As you can see, we keep a healthy inventory to keep up with all of our clients’ demands.

We even plot our own stickers.

13. Our friendly and knowledgeable staff is always sitting by anxiously waiting to answer any questions or place any orders.

They are also very handsome.

Especially the one in glasses.

At least that is what my mother tells me.

So come pay us a visit; after all, seeing is believing.