Ive been wanting to do this for about 5 years now. I really dont know why I didnt, but today was the day.

First off, thanks Izzy for the deal on the brakes. :clap: :dancenana:

Alright, here we go.....

I first want to express my dis-satisfaction with aftermarket brakes. Ive had bad luck with Baer's and Wildwoods. Im pretty sure Im not doing anything wrong, just bad parts. On top of that I think OEM parts far outweigh aftermarket parts in quality, and mostly the extensive R&D that goes into them.

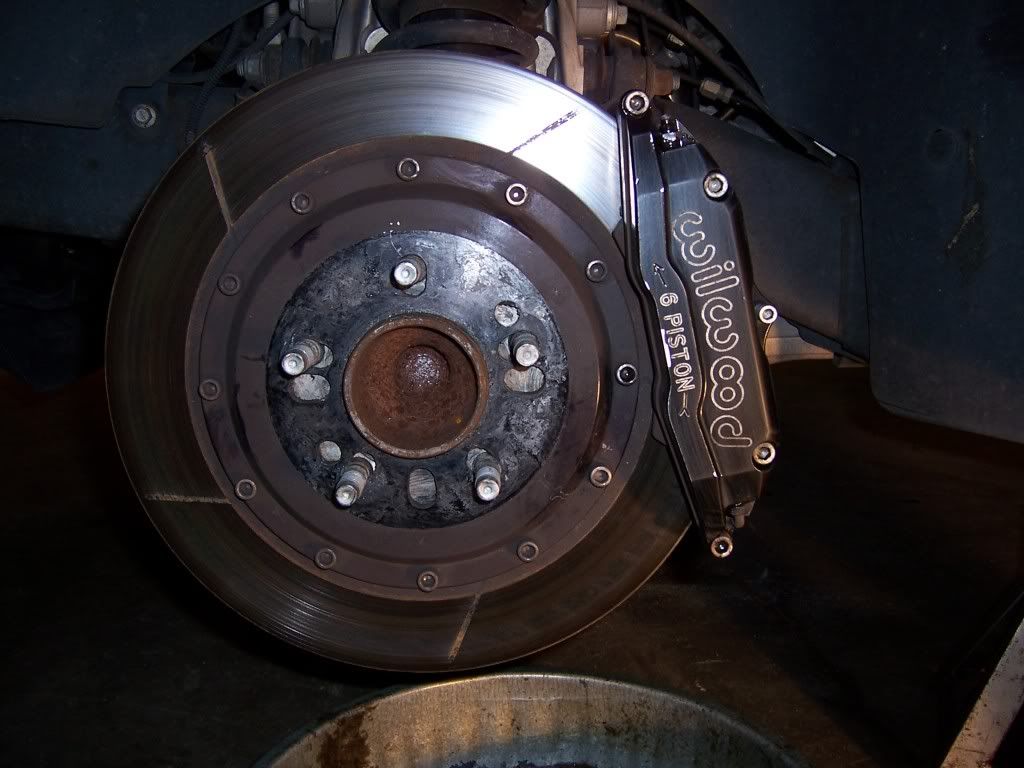

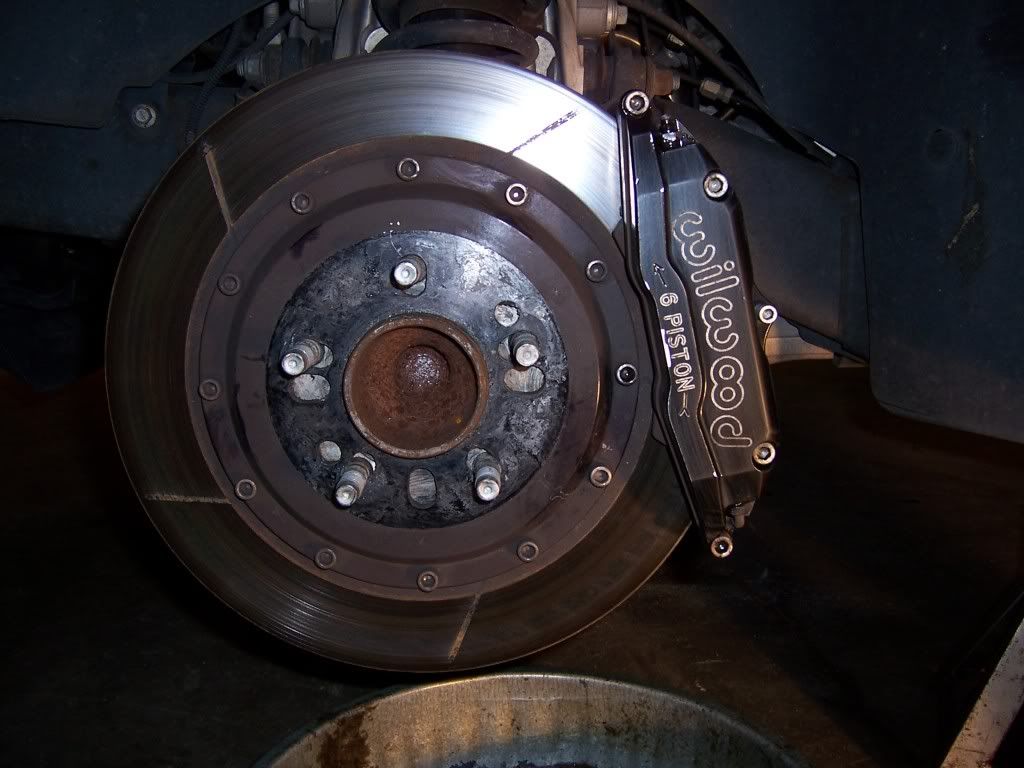

This is on my Blue Marauder, which I had Wildwoods on. At least they stopped pretty good, but the rotors just started to warp. On top of that I am limited to Wildwood pads and the god awful dust that comes with them. ..and also the fact the pad dust clogs up the slots making them useless.

Some observations right of the bat:

A Mach1 rotor (which is far superior to a Wildwood rotor) is a direct bolt on*.

Why they even supplied a 2 piece rotor with less veins is beyond me.

*The Hub ID on a Wildwood rotor is 2.82, Mach hub id is 2.80. Slight enlargement IS necessary, took 3 minutes with a die grinder. Everything else is the same.

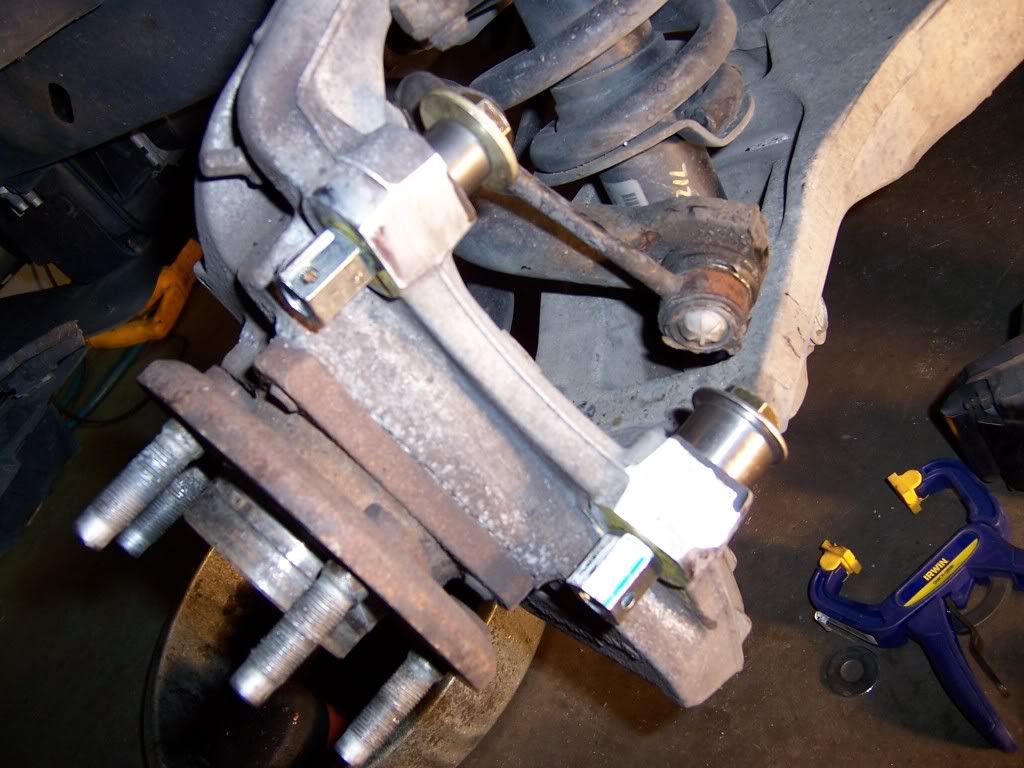

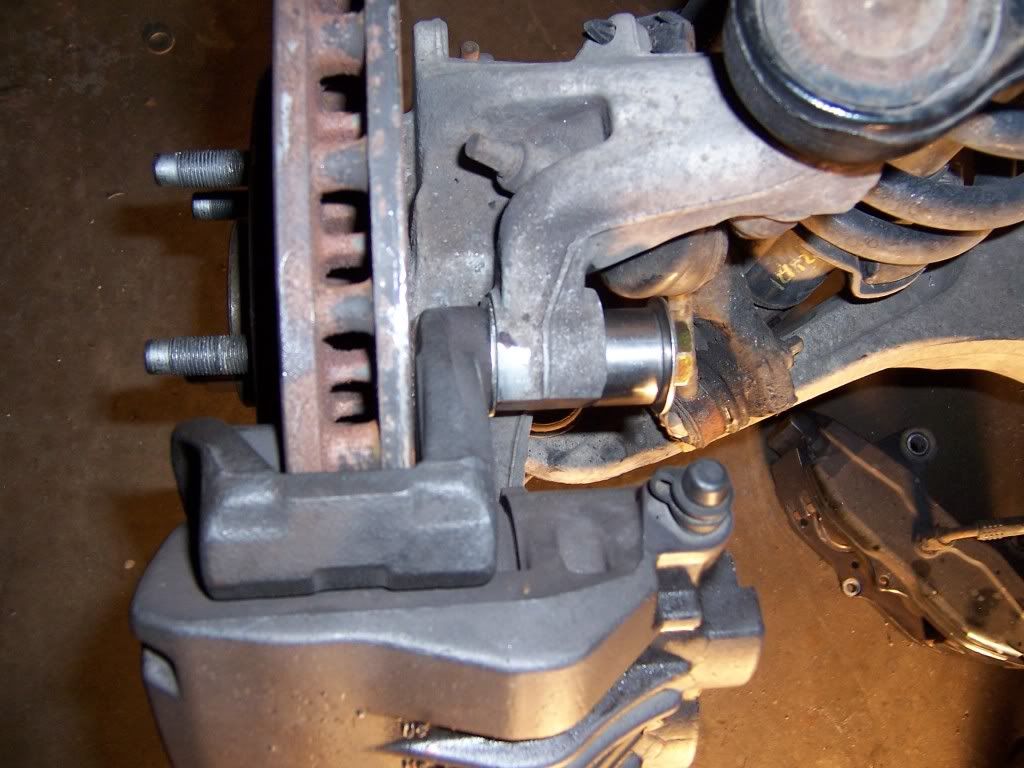

Now the hard part, adapting the Mach bracket to the Marauder Spindle. My intention was to make an adapter bracket so I could offer it to the Marauder community, but thats just not possible with the dimensions I had to work with. I tore my hair out for hours but finally caved and made a trip to Tractor supply for ideas....and found one.

The following pics will explain:

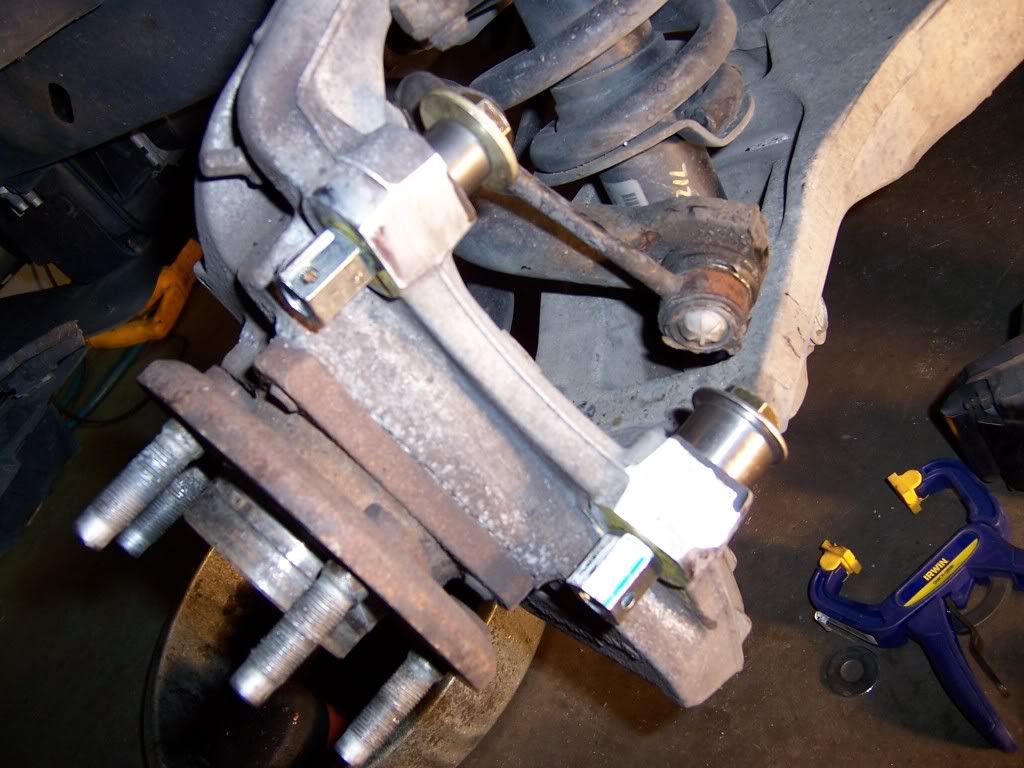

What you see in the vice is a threaded rod coupler! When cut in half the length is spot-on. I then made the cuts to the braket and welded them in. Im not even gonna show you the welds...crude but good. Now keep in mind It took me a while to figure out exactly where to cut the brackets, but my measure twice cut once method proved successful.

Now keep in mind It took me a while to figure out exactly where to cut the brackets, but my measure twice cut once method proved successful.

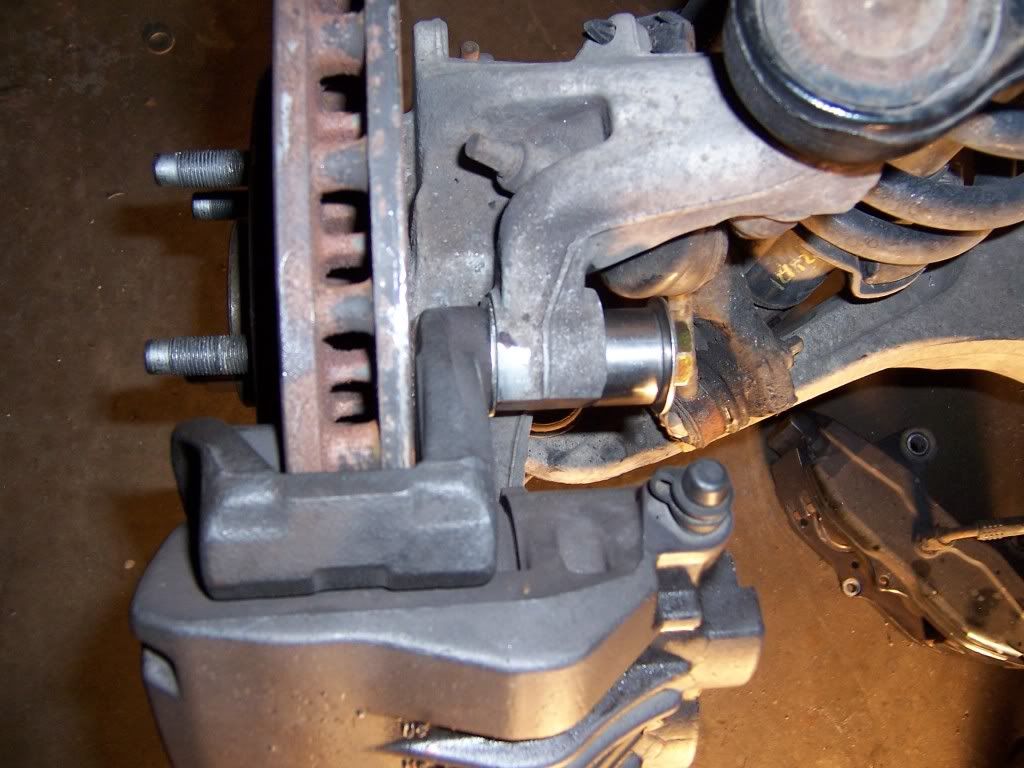

From here on out it was cake. Besides picking up the wrong length bolts, everything fits quite nicely. There is no longer a need for the 1/8" spacer for the Wildwood kit, and fitment of the donut spare is now not even close to the rotor.

Mind you Im not done yet, havent even touched the passenger side (tomorrow ) Bottom line is this, Im in this about $230 so far and I just need to find the proper Stainless Steel brake lines for the new calipers.

) Bottom line is this, Im in this about $230 so far and I just need to find the proper Stainless Steel brake lines for the new calipers.

So this is quite literally 1000 dollars cheaper that aftermarket brakes, readily available used on any Stang forum, and Im not limited to the aftermarket pads, rotors and the insane prices that come with it.

Ill post bak when I do some road testing, but Im quite positive I already know the results. :biggthump

BTW Hi to all the Marauder guys who stop in to visit this thread.

First off, thanks Izzy for the deal on the brakes. :clap: :dancenana:

Alright, here we go.....

I first want to express my dis-satisfaction with aftermarket brakes. Ive had bad luck with Baer's and Wildwoods. Im pretty sure Im not doing anything wrong, just bad parts. On top of that I think OEM parts far outweigh aftermarket parts in quality, and mostly the extensive R&D that goes into them.

This is on my Blue Marauder, which I had Wildwoods on. At least they stopped pretty good, but the rotors just started to warp. On top of that I am limited to Wildwood pads and the god awful dust that comes with them. ..and also the fact the pad dust clogs up the slots making them useless.

Some observations right of the bat:

A Mach1 rotor (which is far superior to a Wildwood rotor) is a direct bolt on*.

Why they even supplied a 2 piece rotor with less veins is beyond me.

*The Hub ID on a Wildwood rotor is 2.82, Mach hub id is 2.80. Slight enlargement IS necessary, took 3 minutes with a die grinder. Everything else is the same.

Now the hard part, adapting the Mach bracket to the Marauder Spindle. My intention was to make an adapter bracket so I could offer it to the Marauder community, but thats just not possible with the dimensions I had to work with. I tore my hair out for hours but finally caved and made a trip to Tractor supply for ideas....and found one.

The following pics will explain:

What you see in the vice is a threaded rod coupler! When cut in half the length is spot-on. I then made the cuts to the braket and welded them in. Im not even gonna show you the welds...crude but good.

From here on out it was cake. Besides picking up the wrong length bolts, everything fits quite nicely. There is no longer a need for the 1/8" spacer for the Wildwood kit, and fitment of the donut spare is now not even close to the rotor.

Mind you Im not done yet, havent even touched the passenger side (tomorrow

So this is quite literally 1000 dollars cheaper that aftermarket brakes, readily available used on any Stang forum, and Im not limited to the aftermarket pads, rotors and the insane prices that come with it.

Ill post bak when I do some road testing, but Im quite positive I already know the results. :biggthump

BTW Hi to all the Marauder guys who stop in to visit this thread.